The size of the machine is very convenient for portable work. Unless it is essential to utilise the torsional. section bending machine design.

Section Bending Machine Design, Unless it is essential to utilise the torsional. Based on the design the volume flow rate in the derived pipe was 45238 10-5 m3s 27 lmin Power was 1273 kW which results in an efficiency of 573. 5 where an I-section fixed at one end is subjected to torsion at the other end.

Pin On Induction Pipe Bending Machine From pinterest.com

Pin On Induction Pipe Bending Machine From pinterest.com

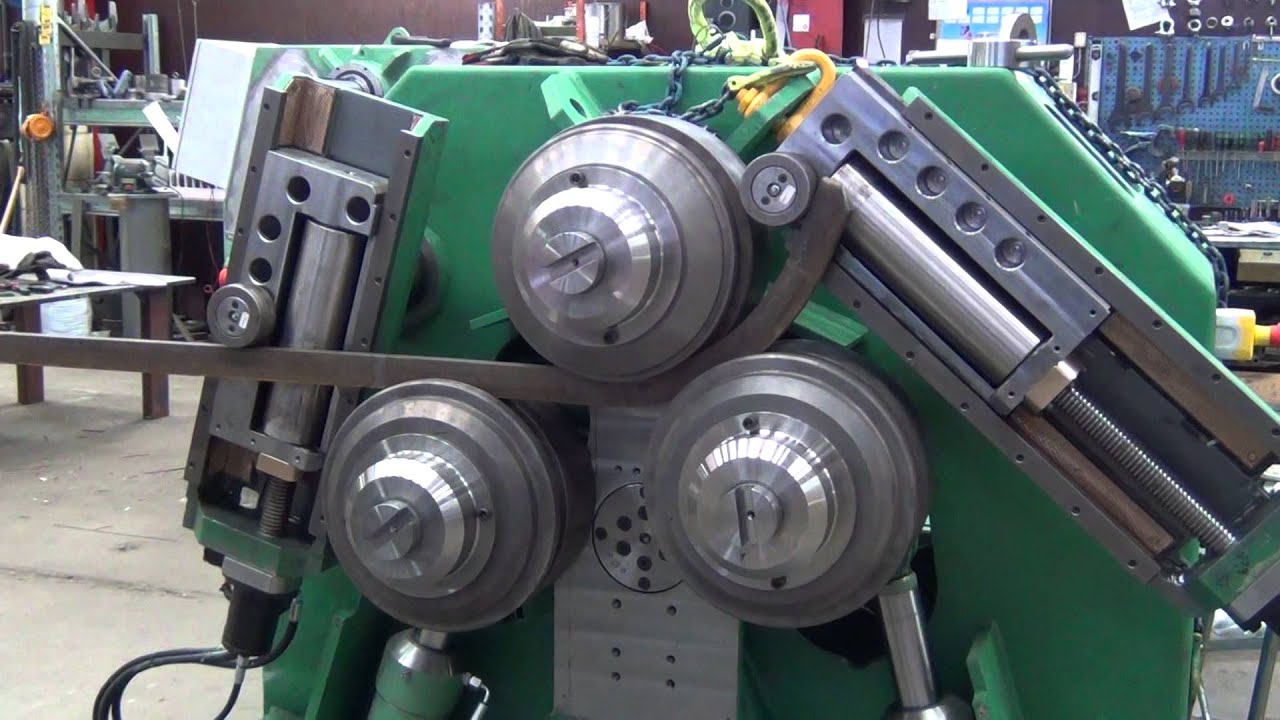

BEAMS SUBJECTED TO TORSION BENDING-II design using box sections tubular hollow sections or lattice box girders which are fully triangulated on all faces. The overall cost of fabrication of. Our Section Bending Machines are available both in Mechanical and Hydraulic models these machines can bend wide range of structural steel sections flat bars solid square or round angle iron leg in or leg out pipes round tube square tube rectangular tubing etc.

The size of the machine is very convenient for portable work.

Moreover it is easy to be carried and used at any time and any place. This machine is used to bend steel into curve or other curvature shape. Is carried out by a particular machine the tube bending machine with which a fixed axial deformation is applied to the tube to be bent deriving from the radius of the mould master. It is fully made by steel. Design a round chinning bar to fit between a jamb 32 in wide and support a 270 lb person. The beam is subjected to pure bending.

Another Article :

On the other hand with roll bending special machines are used the angle rolls equipped with rolls within which tubing box sections and profiles of various dimensions shape and section. 10 Full PDFs related to this paper. Moreover it is easy to be carried and used at any time and any place. The warping restraint causes bending deformation of the flanges in their plane in addition to twisting. Derive the expression for the normal stress due to bending at the extreme fibers of a curved beam. Hpk 80 Hyd Profile Bend Machineflat Bar Spiral 63 Metal Working Tools Metal Bending Tools Sheet Metal Roller.

Which is used to bend bar of any free size with higher speed and desired accuracy. The working size of the designed maximum bending beam is 300mm. Plane sections perpendicular to the axis of the beam remain plane even after bending. The bending deformation is accompanied by a shear. Which is used to bend bar of any free size with higher speed and desired accuracy. Rbm 10e Electric Tubing And Section Bar Round Bending Machine Tools Tool Shadow Tool Railtool And Steel Products Aliexpress Machine Tools Sawing Machine Folding Machine.

It is fully made by steel. Perimeter formulaLπDi S in the formula Di is the cylinder diametermm S is cylinder thicknessmm. The machine is compact and is portable. A short summary of this paper. My project is to design and construct a bending machine. Hydraulic Tube Bender Iron Work Mechanical Design Metal Bender.

All these are more efficient means of resisting torsional moments compared with I or H sections. SweBend offers many different sizes of section and plate bending machines from our smallest model SB3B-55 designed for narrow and small jobs throughout a range of standard machines up to our giant Eliminator-400. Based on the design the volume flow rate in the derived pipe was 45238 10-5 m3s 27 lmin Power was 1273 kW which results in an efficiency of 573. Four rollers CNC control more precise bending. Roll forming roll bending or plate rolling is a continuous bending operation in which a long strip of metal typically coiled steel is passed through consecutive sets of rolls or stands each performing only an incremental part of the bend until the. Pin On مكائن.

4 roll section bender. Perimeter formulaLπDi S in the formula Di is the cylinder diametermm S is cylinder thicknessmm. Design a round chinning bar to fit between a jamb 32 in wide and support a 270 lb person. The working size of the designed maximum bending beam is 300mm. A Textbook of Machine Design by R SKHURMI AND J KGUPTA. Pin On Induction Pipe Bending Machine.

4 roll section bender. Perimeter formulaLπDi S in the formula Di is the cylinder diametermm S is cylinder thicknessmm. The working size of the designed maximum bending beam is 300mm. 1 minimize weight 2 set grip spread to 18 in as shown in the figure 3 diameter of bar to be about. ABSTRACT My project is to design and construct a bending machine. Pin On 3 Makarali Bukum.

There are machine works on pneumatic and hydraulic are also used for making stirrups but those machine has major disadvantage of requirement of large space for storage tank and compressor which makes machine heavy and. 5 where an I-section fixed at one end is subjected to torsion at the other end. Ad Improve Your Business ROI - Get A Better Deal On Pipe Bending Machine. 4 roll profile bending machine. There are machine works on pneumatic and hydraulic are also used for making stirrups but those machine has major disadvantage of requirement of large space for storage tank and compressor which makes machine heavy and. Pin On Mechanical Projects Pdf.

1 minimize weight 2 set grip spread to 18 in as shown in the figure 3 diameter of bar to be about. Be sure you will get the best out of more than 4000 used machines and tools. A short summary of this paper. A Textbook of Machine Design by R SKHURMI AND J KGUPTA. Pipe Bending Machine - Used for bending Round hollow Pipes CAD model Section Bending Machine 3D CAD Model Library GrabCAD Please enable JavaScript to use GrabCAD. Pin On Construction Machinery.

Perimeter formulaLπDi S in the formula Di is the cylinder diametermm S is cylinder thicknessmm. SweBend offers many different sizes of section and plate bending machines from our smallest model SB3B-55 designed for narrow and small jobs throughout a range of standard machines up to our giant Eliminator-400. So our project is to design and develop Bar Bending Machine. Variable size special mould for profile bending machine designed for bending beams. Unless it is essential to utilise the torsional. Pin On Metal Working.

A Textbook of Machine Design by R SKHURMI AND J KGUPTA. Moreover it is easy to be carried and used at any time and any place. A short summary of this paper. Ad Improve Your Business ROI - Get A Better Deal On Pipe Bending Machine. Arms are subjected to bending moment and their section is estimated from bending stress consideration. Cnc Tube Bending Machine Square Rectangular Profiles Tubes Section Bending Youtube Tube Cnc Rectangular.

As the name suggests this project is about fabrication of a machine that is used for bending of pipes. Design a round chinning bar to fit between a jamb 32 in wide and support a 270 lb person. ABSTRACT My project is to design and construct a bending machine. The warping restraint causes bending deformation of the flanges in their plane in addition to twisting. All these are more efficient means of resisting torsional moments compared with I or H sections. Tutorial On How To Bend With A Section Bending Machine Mc150b Nargesa Youtube Metal Bending Tools Inventions Welding Projects.

The size of the machine is very convenient for portable work. Here the member is restrained from warping freely as one end is fixed. 2932 Design of Lever Arms. The size of the machine is very convenient for portable work. A short summary of this paper. Pin On Machine.

Four rollers CNC control more precise bending. Is carried out by a particular machine the tube bending machine with which a fixed axial deformation is applied to the tube to be bent deriving from the radius of the mould master. Which is used to bend bar of any free size with higher speed and desired accuracy. 1 minimize weight 2 set grip spread to 18 in as shown in the figure 3 diameter of bar to be about. This machine is used to bend steel into curve or other curvature shape. Pin On Dural Tube Bending Machine Catalogue.

Perimeter formulaLπDi S in the formula Di is the cylinder diametermm S is cylinder thicknessmm. Figure 294 shows lever with fulcrum located between the load and the effort point. Bending moment is zero at the point of application of forces and is maximum at the fulcrum. There are machine works on pneumatic and hydraulic are also used for making stirrups but those machine has major disadvantage of requirement of large space for storage tank and compressor which makes machine heavy and. The difference between two diagonal lines LL1 L2 2mm length tolerance of cylinder section L3mm. Pin On Induction Pipe Bending Machine.

A short summary of this paper. Roll forming roll bending or plate rolling is a continuous bending operation in which a long strip of metal typically coiled steel is passed through consecutive sets of rolls or stands each performing only an incremental part of the bend until the. BEAMS SUBJECTED TO TORSION BENDING-II design using box sections tubular hollow sections or lattice box girders which are fully triangulated on all faces. Experience and know-how of what it takes to design manufacture and install machines that will be a cornerstone in your production. The size of the machine is very convenient for portable work. Pin On Mecanik.