We use the 4 mix designs shown above for most of our projects. See me explain this page in the video below. job mix design concrete.

Job Mix Design Concrete, We use the 4 mix designs shown above for most of our projects. Estimate the water and air content using ACI 2111 Table 633. Concrete is to enable a concrete technologist to design a concrete mix for a particular strength and durability.

Concrete Cover To Be Provided In Rcc Concrete Cover Civil Engineering Construction Civil Engineering Design From in.pinterest.com

Concrete Cover To Be Provided In Rcc Concrete Cover Civil Engineering Construction Civil Engineering Design From in.pinterest.com

Concrete mix designs are submitted for review so that the reviewer can verify the contractor is interpreting the construction documents correctly. If possible and to provide the best service we try to have more material on the truck than you order just in case you need more than you order. Concrete mix design is the process of selecting suitable ingredients of concrete and determine the relative proportions to produce concrete with certain performance and.

Types of Concrete Mix Ratio - Mix Designs Nominal Concrete Mix Ratios In the past the specifications for concrete prescribed the proportions of cement fine and coarse aggregates.

Select the water-cement ratio. However if not given an appropriate value may be chosen from Table 1. Trial mixtures made with actual job materials to determine the relationship between the ratio and strength. Name of concrete supplier and source of materials should be shown as a change in these variables can affect the quality of the mix. May be used only for very small jobs when the 28-day strength of. We offer a guide to help you find your perfect read mix.

Another Article :

To know the Concrete Mix Design follow below-. The mix design of Aspahltic concrete is carried out by Marshall Mix Design and end result of a successful mix design is a recommended mixture of aggregate and asphalt binder. These guidelines were developed to assist the engineer reviewing concrete mix designs. See me explain this page in the video below. For example if the concrete needs to be pumped on top of a building is for making a slab or a bridge each scenario will require a different way to design the concrete mix. Mob Job Concept Creative Packaging Design Concept Fast Setting Concrete.

Decide workability in terms of slump for the type of job in hand. We bring all the materials to the job site housed in bins and compartments within our mobile mixing trucks. Strength The specified compressive strength at 28 days is the. The main body of the guidelines focuses on the process of reviewing the mix design. Recommended ratios will enable you to mix concrete to match the function for which it is intended. How To Mix Concrete With Ease Mix Concrete Concrete Mixes Concrete.

At Concrete Supply Co we sleep better at night knowing our end-to-end ready mix concrete solution meets the highest quality performance in concrete and our integrity in doing so is unparalleled. Estimate the average design strength using standard deviation or as it is specified for the special job. This recommended mixture which also includes aggregate gradation and asphalt binder type is often referred to as the job mix formula JMF. To know the Concrete Mix Design follow below-. Set verifies that a concrete mixture meets design re-quirements prior to use in construction. Runner Up Design By Grafix Euu Contest Design Ready Mixed Concrete Computer Aided Engineering.

Job address should be shown. We desire a moderate ce-ment-to-aggregate ratio of 110 per ratio listings on page 368. As a general rule the lowest slump. For example if the concrete needs to be pumped on top of a building is for making a slab or a bridge each scenario will require a different way to design the concrete mix. Non-Air-Entrained Concrete Mix Design Procedures ACI Mix Design Maximum aggregate size in Slumpin 0375 05 075 1 15 2 3 6 1 to 2 305 295 280 270 250 240 225 180. Prodyogi A Civil Engineering Blog Proportioning Of Concrete Mix Methods Of Concret Concrete Mixes Concrete Mix Design Concrete.

Our experience in produc-ing similar units indicates that a good total water con-. Types of Concrete Mix Ratio - Mix Designs Nominal Concrete Mix Ratios In the past the specifications for concrete prescribed the proportions of cement fine and coarse aggregates. Make sure the mix design has a designation. Using the ACI 2111 method here is an abbreviated run-through on how to design a mix. Im going to show you the actual batch plant ticket they give me when the concrete trucks show up on the job and we pour the concrete. Concrete Estimating Concrete Bleeding Bleeding In Concrete Concrete Mix Design Concrete Mixes Concrete.

Set verifies that a concrete mixture meets design re-quirements prior to use in construction. Non-Air-Entrained Concrete Mix Design Procedures ACI Mix Design Maximum aggregate size in Slumpin 0375 05 075 1 15 2 3 6 1 to 2 305 295 280 270 250 240 225 180. The design of concrete mix is not a simple task on account of the widely varying properties of the constituent materials the conditions that prevail at the site of work in particular the exposure condition and the conditions that are demanded for a particular work for which the mix is designed. We use the 4 mix designs shown above for most of our projects. General guidance can be taken from table 117. Pin On Leotlela Jerry.

The extent of QC Quality Control is often an economic compromise and depends on the type and size job. Strength The specified compressive strength at 28 days is the. Our experience in produc-ing similar units indicates that a good total water con-. Trial mixtures made with actual job materials to determine the relationship between the ratio and strength. Find the V a for each component from. Fast Setting Concrete Mix Recipe Ingredients Mix Design Fast Setting Concrete Concrete Mixes Concrete Mix Design.

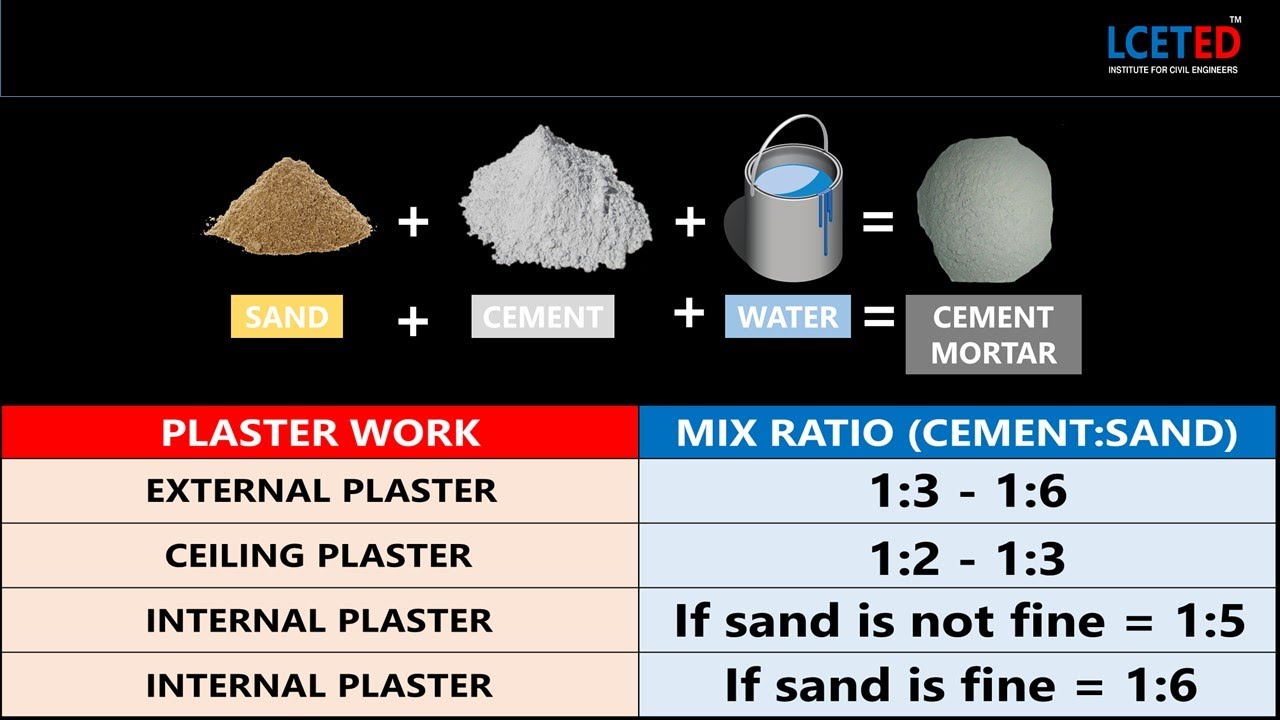

The main body of the guidelines focuses on the process of reviewing the mix design. Can any one assist me to know the proportion for 20MPA Concrete Design Mix. For the required aggregate design batch weight of 4500 pounds the required cement is. The main body of the guidelines focuses on the process of reviewing the mix design. This high strength concrete mix design has been developed by B. Cement Mortar Mix Ratio And Its Application Lceted Mixratio In 2021 Engineering Notes Civil Engineering Design Civil Engineering Handbook.

We can also change the mix design at the touch of a button to produce different types of concrete from the same load of materials. The mix design of Aspahltic concrete is carried out by Marshall Mix Design and end result of a successful mix design is a recommended mixture of aggregate and asphalt binder. The main body of the guidelines focuses on the process of reviewing the mix design. Concrete mix design is a balancing. Estimate the average design strength using standard deviation or as it is specified for the special job. How To Mix Concrete Perfectly Every Time Mix Concrete Concrete Concrete Crafts.

A quality concrete mix design is crucial for successful construction. As a general rule the lowest slump. Estimate the average design strength using standard deviation or as it is specified for the special job. The main body of the guidelines focuses on the process of reviewing the mix design. This recommended mixture which also includes aggregate gradation and asphalt binder type is often referred to as the job mix formula JMF. How Do I Resolve Moisture Issues In 2021 Polished Concrete Flooring Polished Concrete Concrete Floors.

Types of Concrete Mix Ratio - Mix Designs Nominal Concrete Mix Ratios In the past the specifications for concrete prescribed the proportions of cement fine and coarse aggregates. For example if the concrete needs to be pumped on top of a building is for making a slab or a bridge each scenario will require a different way to design the concrete mix. The design of concrete mix is not a simple task on account of the widely varying properties of the constituent materials the conditions that prevail at the site of work in particular the exposure condition and the conditions that are demanded for a particular work for which the mix is designed. However if not given an appropriate value may be chosen from Table 1. Batching Generally materials for smaller jobs are batched by volume. Pin On Pdf Books.

Choose the target slump. To know the Concrete Mix Design follow below-. The art of concrete mix design and concrete mix ratios is to create the right collection of these properties for a given concreting job. On-site mixed concrete from On-Demand Concrete is mixed at the jobsite so it is always fresh. To determine the volume obtained for the job add the absolute volume V a of the four componentscements gravel sand and water. Cement Mortar Mix Ratio And Its Application Lceted Mixratio In 2021 Engineering Notes Civil Engineering Design Civil Engineering Handbook.

We offer a guide to help you find your perfect read mix. If possible and to provide the best service we try to have more material on the truck than you order just in case you need more than you order. Select the water-cement ratio. Batching Generally materials for smaller jobs are batched by volume. The extent of QC Quality Control is often an economic compromise and depends on the type and size job. Sakrete 5000 Plus 80 Lb Concrete Mix 65200370 The Home Depot Concrete Mixes Concrete Concrete Mix Design.

These guidelines were developed to assist the engineer reviewing concrete mix designs. The mix design of Aspahltic concrete is carried out by Marshall Mix Design and end result of a successful mix design is a recommended mixture of aggregate and asphalt binder. These guidelines were developed to assist the engineer reviewing concrete mix designs. Job address should be shown. When you have had enough concrete the truck stops mixing more and the remaining sand gravel cement and water just stay in their separate bins on the truck. Concrete Mix Design As Per Is Code In 2021 Concrete Mix Design Concrete Mixes Concrete.

This recommended mixture which also includes aggregate gradation and asphalt binder type is often referred to as the job mix formula JMF. We offer a guide to help you find your perfect read mix. To know the Concrete Mix Design follow below-. Set verifies that a concrete mixture meets design re-quirements prior to use in construction. These guidelines were developed to assist the engineer reviewing concrete mix designs. Fast Setting Concrete Mix Recipe Ingredients Mix Design Fast Setting Concrete Concrete Mixes Concrete.