Case study is our Razor scooter hub motor a BLDC motor designed inside a 5 diameter wheel. LM5060-Q1 is a high-side protection controller with controlled output rise time. bldc motor design calculations.

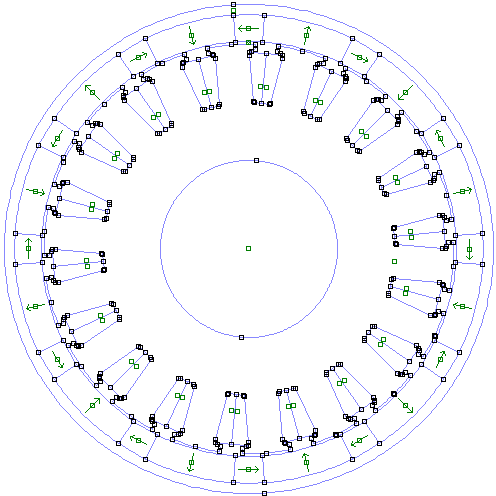

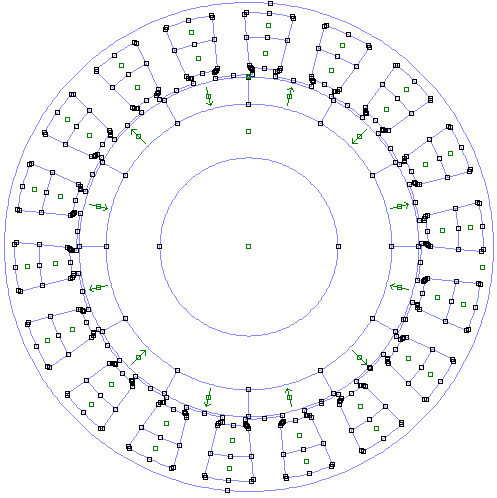

Bldc Motor Design Calculations, TPS40210-Q1 is a current-mode boost controller with 45-V to 52-V input. For larger diameter andor motors that rotate more slowly a higher slot and pole count can be used such as 24s26p with a reduced number of turns per tooth and thinner Fe-Si laminations. Simulation results from the design software tool focuses on the torque and magnetic flux density distribution.

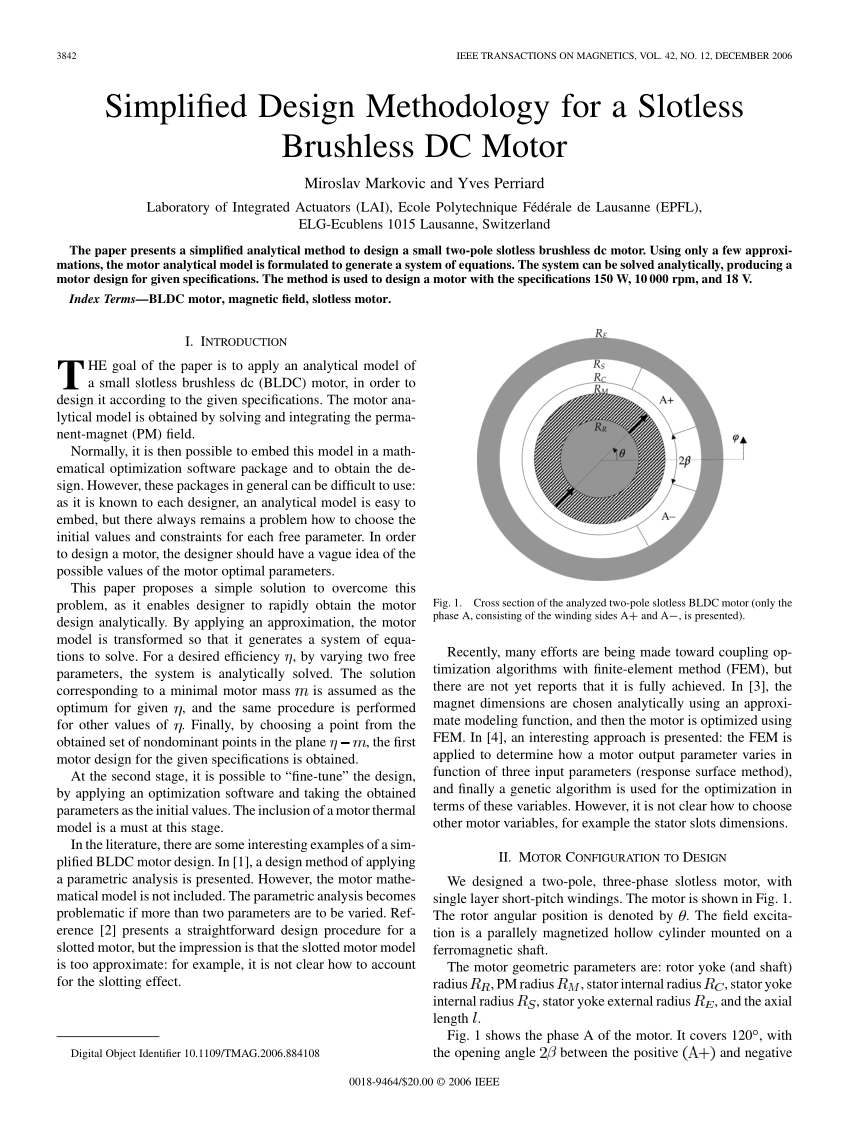

Pdf Simplified Design Methodology For A Slotless Brushless Dc Motor From researchgate.net

Pdf Simplified Design Methodology For A Slotless Brushless Dc Motor From researchgate.net

A DC motor is connected to a source of 150 V and its armature resistance is 075 Ohms. Fundamental Physics Electric motors transform power from the electrical domain to the mechanical domain using magnetic interaction. Case study is our Razor scooter hub motor a BLDC motor designed inside a 5 diameter wheel.

Through numerical analysis the basic dimensions are ascertained and the winding features are determined.

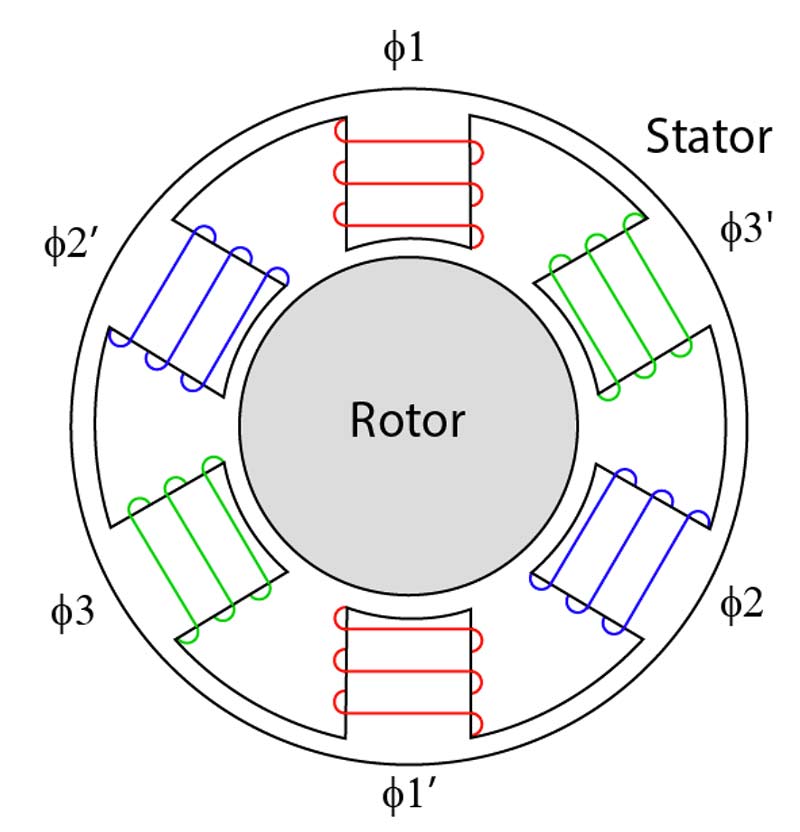

Hall sensor spacing mechanical angle calculation formula. Simulation results from the design software tool focuses on the torque and magnetic flux density distribution. The BLDC motor is modelled using MATLAB SIMULINK and the dynamic characteristics of PMBLDC motor are monitored. How to estimate the torque of a BLDC PMSM electric motor using only its Kv and current draw. FEA techniques were used to optimize the dimensions with a target motor constant K m selected according to 1. A permanent-magnet 3-phase brushless DC electric motor is attached to a load.

Another Article :

Motor is operated with vESC66 inverter which is software-limited to 140A. In a BLDC motor this magnetic interaction occurs between coils of wire. Electric and magnetic loading calculation 5. UCC27201A-Q1 is a high-side and low-side driver capable of driving at voltages up to 120-V. LM5060-Q1 is a high-side protection controller with controlled output rise time. Armature Reaction Field And Inductance Calculation Of Ironless Bldc Motor Semantic Scholar.

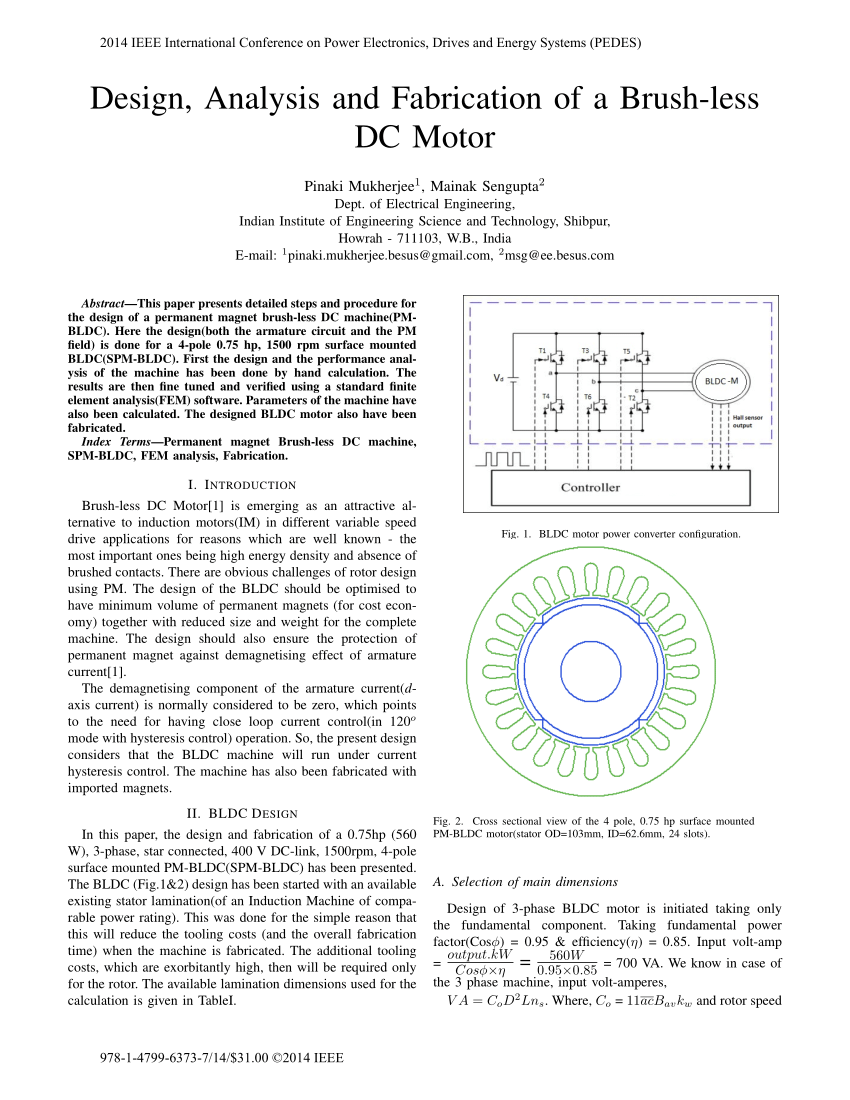

τ 83 I A KV τ 83 I A K V. Hall sensor spacing mechanical angle calculation formula. What I have been unable to find is an online calculator. May 15 2020 by masuzi. For BLDC motor drive applications. Pdf Design Analysis And Fabrication Of A Brush Less Dc Motor.

- Hall sensor table for a BLDC motor will be similar to the table below for 120deg hall sensor. TPS40210-Q1 is a current-mode boost controller with 45-V to 52-V input. Can you also tell me the design of this 45kw bldc motor controller please I shell be thankfull. This is shown in Equation 7. 1 The starting current. Brushless Dc Motors Introduction For Next Generation Missile Actuation Systems Outline Analog Devices.

- Hall sensor table for a BLDC motor will be similar to the table below for 120deg hall sensor. One of the key design challenges of a BLDC motor controller lies in determining the position of the rotor. Stator and rotor slot dimensioning 3. - Hall sensor table for a BLDC motor will be similar to the table below for 120deg hall sensor. Main dimension calculations Stator OD ID and stack length 2. Step 5 Motor Selection The Uav Chronicles.

For larger diameter andor motors that rotate more slowly a higher slot and pole count can be used such as 24s26p with a reduced number of turns per tooth and thinner Fe-Si laminations. This application report provides an in-depth discussion of thermal design for three-phase integrated BLDC motor drive PCBs in context of the DRV10987. The design of a small-sized slotless BLDC motor. LM5060-Q1 is a high-side protection controller with controlled output rise time. Performance curve xc xlsx brushless dc motor control made easy best concrete design excel spreadsheet electrical ms excel spreadsheets. How Brushless Motor And Esc Work Howtomechatronics Electronics Projects For Beginners Free Energy Projects Free Energy.

Through numerical analysis the basic dimensions are ascertained and the winding features are determined. Back-EMF calculation with respect to the number of sliced regions. 3602 6 pole pairs number. Equivalent circuit calculation 6. Case study is our Razor scooter hub motor a BLDC motor designed inside a 5 diameter wheel. Outer Rotor Bldc Motor With Surface Mounted Magnets.

Ttr its the time it takes to go 60 electrical degrees or 16 electrical period electrical frequency 16 ttr multiply by 2xpi to get rds multiply by number of pole pairs P to get mechanical speed multiply electrical frequency by 60xP to get RPM. A BLDC generator for energy-harvesting was designed to produce 50-200 watts at shaft speeds of 500-1300 rpm. This is how the calculation works. How to calculate new dc motor parameters of a modified winding. Performance Curve Xc Xlsx Brushless Dc Motor Control Made Easy. Winding Layout Of A 9 Slots 8 Poles Bldc Machine With Non Overlapping Download Scientific Diagram.

Combining various methods to achieve the desired result. This is how the calculation works. Using a suitable sensing device. Motor is operated with vESC66 inverter which is software-limited to 140A. To complete this part of DC Motor Calculations lets look at a simple problem. Inner Rotor Bldc Motor With Surface Mounted Magnets.

You can accomplish this in different ways such as. Combining various methods to achieve the desired result. To complete this part of DC Motor Calculations lets look at a simple problem. I understand the the number of poles on the stator the number of magnets on the rotor how you bundle the stator teeth into poles and a great deal of factors explained here. There exists a fundamental relationship between an electric motors velocity constant KV K V armature current IA I A and torque τ τ. Choosing Between Brush And Brushless Dc Motors Allied Motion.

What I have been unable to find is an online calculator. Using a suitable sensing device. Construction of BLDC Motor. 1 The starting current. A DC motor is connected to a source of 150 V and its armature resistance is 075 Ohms. Cross Section Of The Analyzed Two Pole Slotless Bldc Motor Only The Download Scientific Diagram.

Construction of BLDC Motor. Construction of BLDC Motor. 1 The starting current. The BLDC motor is modelled using MATLAB SIMULINK and the dynamic characteristics of PMBLDC motor are monitored. When the motor runs at 800 rpm and when running at 1200. Processes Free Full Text A Study On A Slotless Brushless Dc Motor With Toroidal Winding Html.

This is shown in Equation 7. This application report provides an in-depth discussion of thermal design for three-phase integrated BLDC motor drive PCBs in context of the DRV10987. Bldc Motor Design Calculations Excel Sheet. A BLDC generator for energy-harvesting was designed to produce 50-200 watts at shaft speeds of 500-1300 rpm. You can accomplish this in different ways such as. 45kw Bushless Motor Design Brushless Motors 3phase Inverters Schematics.

BLDC motors do not experience the slip that is normally seen in induction motors. This is shown in Equation 7. I understand the the number of poles on the stator the number of magnets on the rotor how you bundle the stator teeth into poles and a great deal of factors explained here. This means the magnetic field generated by the stator and the magnetic field generated by the rotor rotate at the same frequency. Bldc Motor Design Calculations Excel Sheet. Brushless Dc Bldc Motor Construction And Working Electricaleasy Com.

LM5060-Q1 is a high-side protection controller with controlled output rise time. A permanent-magnet 3-phase brushless DC electric motor is attached to a load. Fundamental Physics Electric motors transform power from the electrical domain to the mechanical domain using magnetic interaction. Performance curve xc xlsx brushless dc motor control made easy best concrete design excel spreadsheet electrical ms excel spreadsheets. Main dimension calculations Stator OD ID and stack length 2. What Is Brushless Dc Motor Bldc Construction Working Work Application Motor Free Energy Generator.

BLDC motors come in single-phase 2-phase and 3-phase configurations. Measured efficiency at maximum power is 81. TPS62152-Q1 is a step-down converter with 3-V to 17-V Input and output current up to 1 A. The armature generates 40 V when running at a speed of 400 rpm. One of the key design challenges of a BLDC motor controller lies in determining the position of the rotor. Pdf Design And Modelling Of Bldc Motor For Automotive Applications Semantic Scholar.