Ad Learn The Fundamental Concepts Principles And Transfer Operations In Bioreactors. Copyright 2016 WileyVCH Verlag GmbH Co. bioreactor design and operation.

Bioreactor Design And Operation, Ad Learn The Fundamental Concepts Principles And Transfer Operations In Bioreactors. Join millions of students from 195 countries. Chemical Reactor Design and Operation K.

Pdf 1 Challenges For Bioreactor Design And Operation Semantic Scholar From semanticscholar.org

Pdf 1 Challenges For Bioreactor Design And Operation Semantic Scholar From semanticscholar.org

Size of Fermentors. In the bubble column bioreactor the mechanical impeller is exchanged with raising bubbles which in the case of an aerobic fermentation will anyhow be required and to the benefit of fewer. The bioreactor provides a central link between the starting feedstock and the product.

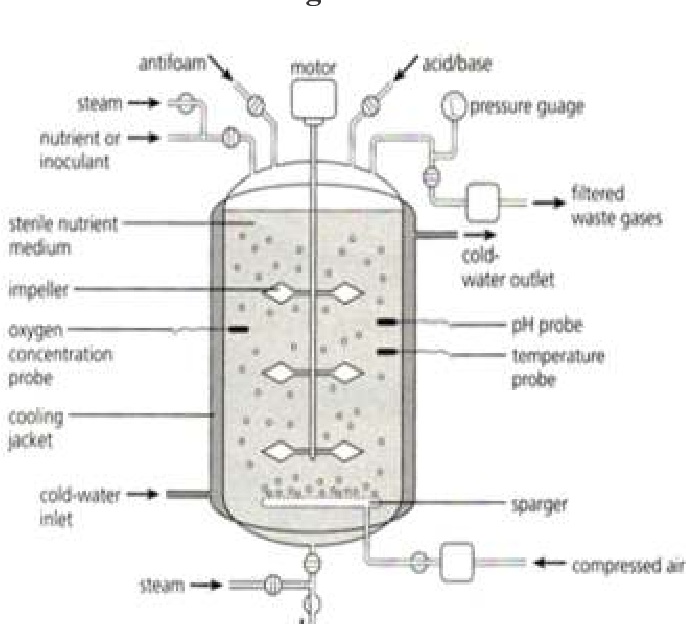

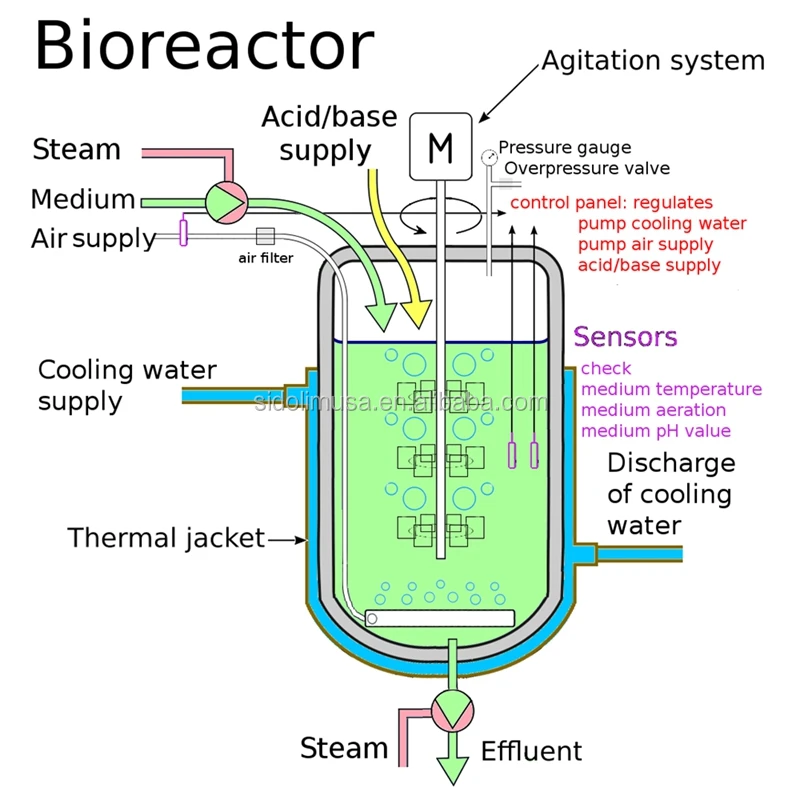

1 suspended-growth in which microorganisms are suspended in cultivation media and 2 attached-growth where the pack of microorganisms are attached and exposed to cultivation media 35 41.

9783527337682 Online ISBN. Copyright 2016 WileyVCH Verlag GmbH Co. CIP SYSTEM DESIGN AND OPERATION General design principles Typically SS304 construction of CIP systems is satisfactory although the non-CIP processing equipment is generally made of SS316L. Click to expand document information. Chemostat with Cell Recycle - to keep the cell concentration higher than the normal steady-state level. John Wiley Sons May 16 2016 - Science - 520 pages.

Another Article :

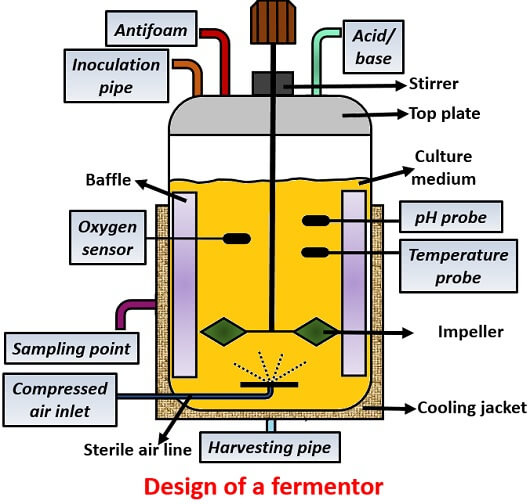

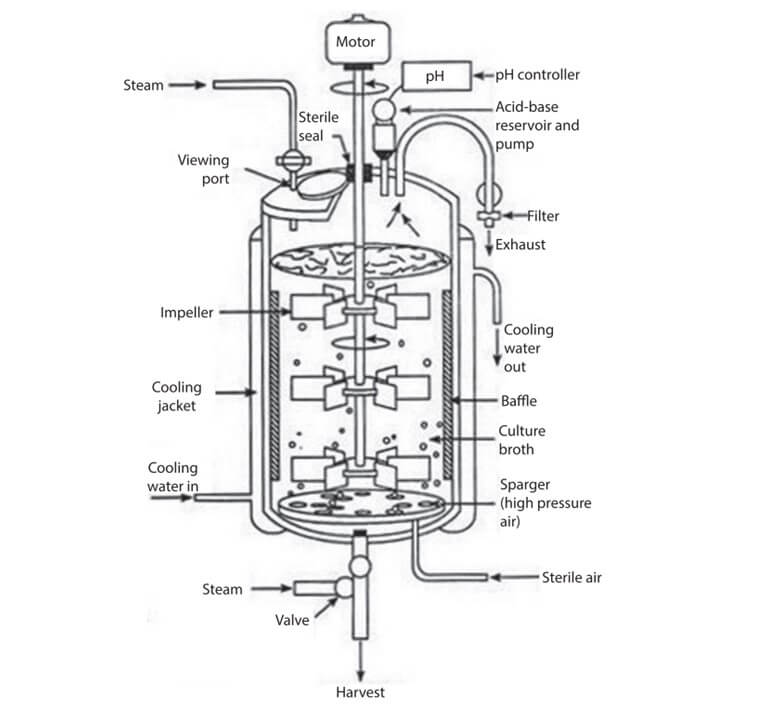

Landfill Bioreactor Design and Operation covers the history and background of landfill technology research studies of actual bioreactor landfills expected leachate and gas yields specific design criteria operation guidelines and reuse of landfill sites to avoid having to establish new sites. The size of fermentors ranges from 1-2 litre laboratory fementors to 500000 litre or occasionally even more fermentors of upto 12 million litres have been used. Copyright 2016 WileyVCH Verlag GmbH Co. Plug-flow mode In a plug-flow reactor the substrate enters one end of a cylindrical tube with is packed with immobilized enzyme and the product steam leaves at the other end. Design Operation and Novel Applications. Bioreactor Operation An Overview Sciencedirect Topics.

C C r t C C K s s s s m 0 max ln 0 F Cs0 F Cs t 0 F V W An ideal plug-flow reactor can approximate the long tube packed-bed and hollow. 101A a disperse gas bubbles throughout tank b increase residence time of bubbles c shear large bubbles to smaller bubbles d disk type or turbine type d I. 16 Using Conceptual Design Methodology 20. As a consequence biochemical reaction engineering. The bioreactor provides a central link between the starting feedstock and the product. Bioreactors Technology Design Analysis Semantic Scholar.

14 Recent Trends in Designing and Operating Bioreactors 12. Improvements in sensor technology and the dynamical models of bioreactors are critical to improvements in control. The size of fermentors ranges from 1-2 litre laboratory fementors to 500000 litre or occasionally even more fermentors of upto 12 million litres have been used. Bioreactor operations are categorized into two main forms. The bioreactor provides a central link between the starting feedstock and the product. Pdf 1 Challenges For Bioreactor Design And Operation Semantic Scholar.

In this expert handbook both the topics and contributors are selected so as to provide an authoritative view of possible applications for this new technology. US EPA WORKSHOP ON BIOREACTORS FEBRUARY 27-28 2003. Design Operation and Novel Applications. The bioreactor provides a central link between the starting feedstock and the product. Join millions of students from 195 countries. Chemical Engineering Aspects Bioreactor A Bioreactor Refers To Any Manufactured Device Or System That Supports A Biologically Active Environment 1 In One Case A Bioreactor Is A Vessel In Which A Chemical.

CIP SYSTEM DESIGN AND OPERATION General design principles Typically SS304 construction of CIP systems is satisfactory although the non-CIP processing equipment is generally made of SS316L. Chemical Reactor Design and Operation K. Join millions of students from 195 countries. 12 Biotechnology Milestones with Implications on Bioreactor Design 2. The size of fermentors ranges from 1-2 litre laboratory fementors to 500000 litre or occasionally even more fermentors of upto 12 million litres have been used. Bioreactor Parts And Their Functions Bioreactor Design Stainless Fermenter For Sale Buy Stainless Fermenter For Sale 15 Gallon Fermenter Stainless Beer Fermentation Tanks Homebrew Product On Alibaba Com.

CIP SYSTEM DESIGN AND OPERATION General design principles Typically SS304 construction of CIP systems is satisfactory although the non-CIP processing equipment is generally made of SS316L. Ad Learn The Fundamental Concepts Principles And Transfer Operations In Bioreactors. Design and Operation of Bioreactors Types of Bioreactors 1. Click to expand document information. 1 Challenges for Bioreactor Design and Operation 1 Carl-Fredrik Mandenius. Pdf 1 Challenges For Bioreactor Design And Operation Semantic Scholar.

Unlimited Access To Free Online Courses. 100 1 100 found this document useful 1 vote 303 views 19 pages. Copyright 2016 WileyVCH Verlag GmbH Co. Plug-flow mode In a plug-flow reactor the substrate enters one end of a cylindrical tube with is packed with immobilized enzyme and the product steam leaves at the other end. Design Operation and Novel Applications. Bioreactor Design For Algal Growth As A Sustainable Energy Source Sciencedirect.

Bioreactor operations are categorized into two main forms. Chemical Reactor Design and Operation K. Unlimited Access To Free Online Courses. 14 Recent Trends in Designing and Operating Bioreactors 12. Landfill Bioreactor Design and Operation covers the history and background of landfill technology research studies of actual bioreactor landfills expected leachate and gas yields specific design criteria operation guidelines and reuse of landfill sites to avoid having to establish new sites. Bioreactor Design An Overview Sciencedirect Topics.

Bioreactor Operation Modes 2. Unlimited Access To Free Online Courses. 16 Using Conceptual Design Methodology 20. The concepts of bioreactor design and operation harbor a wide set of engineering theory methodologies and tools founded on the capacity of biological systems to produce and convert products. Click to expand document information. Bioreactor Operation Modes As Feeding Strategies In Hpsc Expansion Download Scientific Diagram.

When plant scale designs are evolved is important to understand the hydrodynamics in large scale reactor prior to constructionCFD analysis to predict reactor performance in termsof mixing and gas distribution profiles power consumption mass transfer coefficients oxygen transfer rate and shear rate distribution in the large scale bioreactors have been useful in design analysis and. Beenackers Chemical Reaction Engineering Laboratories Twente University of Technology Enschede The Netherlands This is a comprehensive handbook on the design and operation of chemical reactors which are vital elements in every. In the bubble column bioreactor the mechanical impeller is exchanged with raising bubbles which in the case of an aerobic fermentation will anyhow be required and to the benefit of fewer. John Wiley Sons May 16 2016 - Science - 520 pages. The bioreactor provides a central link between the starting feedstock and the product. Pdf 1 Challenges For Bioreactor Design And Operation Semantic Scholar.

14 Recent Trends in Designing and Operating Bioreactors 12. 12 Biotechnology Milestones with Implications on Bioreactor Design 2. Design and Operation of Bioreactors Types of Bioreactors 1. For ease of cleaning bioreactors with electropolished surface finish of Ra. Size of Fermentors. Bioreactors Design Operation And Novel Applications Wiley.

Design Operation and Novel Applications. 14 Recent Trends in Designing and Operating Bioreactors 12. The main shortcoming of the stirred bioreactor its mechanical agitation is solved in other bioreactor designs. Click to expand document information. Copyright 2016 WileyVCH Verlag GmbH Co. Bioreactor Definition Design Principle Parts Types Applications Limitations.

The bioreactor provides a central link between the starting feedstock and the product. In this expert handbook both the topics and contributors are selected so as to provide an authoritative view of possible applications for this new technology. The still expanding field of biotechnology generates all the time new challenges for exploiting this knowledge and these skills. The concepts of bioreactor design and operation harbor a wide set of engineering theory methodologies and tools founded on the capacity of biological systems to produce and convert products. Design Operation and Novel Applications. Criteria For Fermentor Designing Biology Ease.

As a consequence biochemical reaction engineering. The reaction yield and selectivity are determined by the biocatalyst but productivity is often determined by the process technology. Ad Learn The Fundamental Concepts Principles And Transfer Operations In Bioreactors. John Wiley Sons May 16 2016 - Science - 520 pages. 100 1 100 found this document useful 1 vote 303 views 19 pages. Bioreactor Definition Design Principle Parts Types Applications Limitations.

Beenackers Chemical Reaction Engineering Laboratories Twente University of Technology Enschede The Netherlands This is a comprehensive handbook on the design and operation of chemical reactors which are vital elements in every. Ad Learn The Fundamental Concepts Principles And Transfer Operations In Bioreactors. The reaction yield and selectivity are determined by the biocatalyst but productivity is often determined by the process technology. 16 Using Conceptual Design Methodology 20. Lecture Notes-Bioreactor Design and Operation-1. Design And Performance Of Single Use Stirred Tank Bioreactors Bioprocess Internationalbioprocess International.