Design procedure for Bevel Gear. φ Pressure Angle a Addendum a G Addendum of Gear a P. bevel gear design formula.

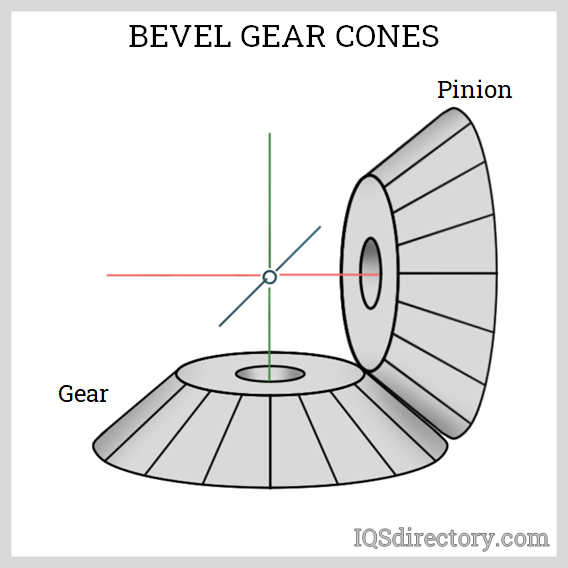

Bevel Gear Design Formula, Cone-shaped bevel gears are produced for the power transmission between these shafts. Bevel gears are most often mounted on shafts that are 90 degrees apart but can be designed to work at other angles as well. Might be applied for bevel gears manufactured by forging molding or 3D printing.

Helical Gear Calculations Crossed Helical Gear Meshes And Bevel Gearing Sdpsi From sdp-si.com

Helical Gear Calculations Crossed Helical Gear Meshes And Bevel Gearing Sdpsi From sdp-si.com

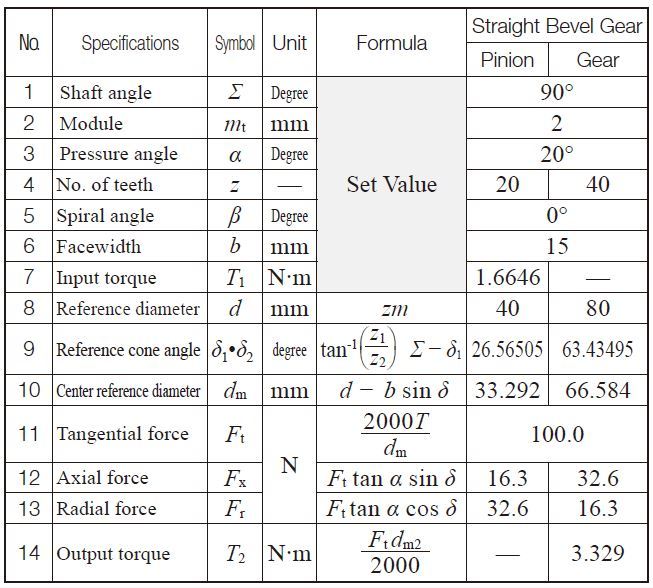

D 1 z 1 m. Bevel gears are used for the power transmission between non-parallel shafts. Equation 2 is the fundamental equation for the planar involute curve.

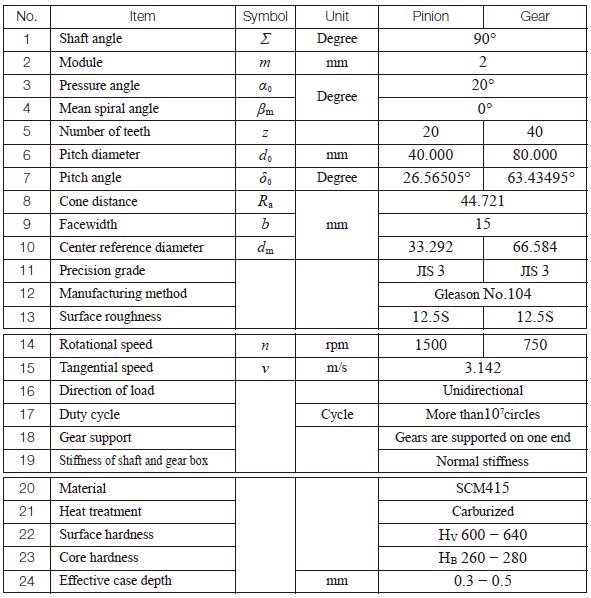

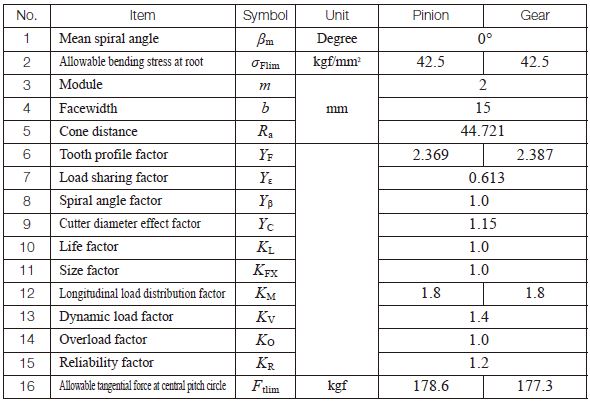

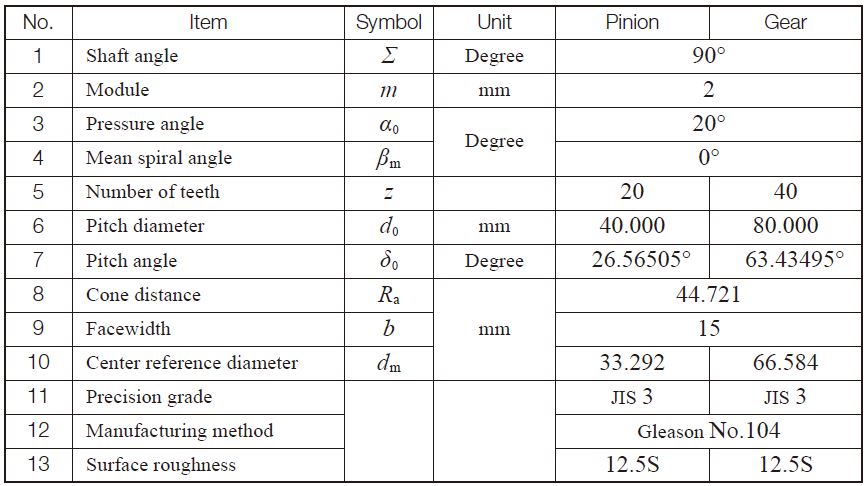

Formula of bevel gears on bending strength JGMA403-01 The Lewis formula.

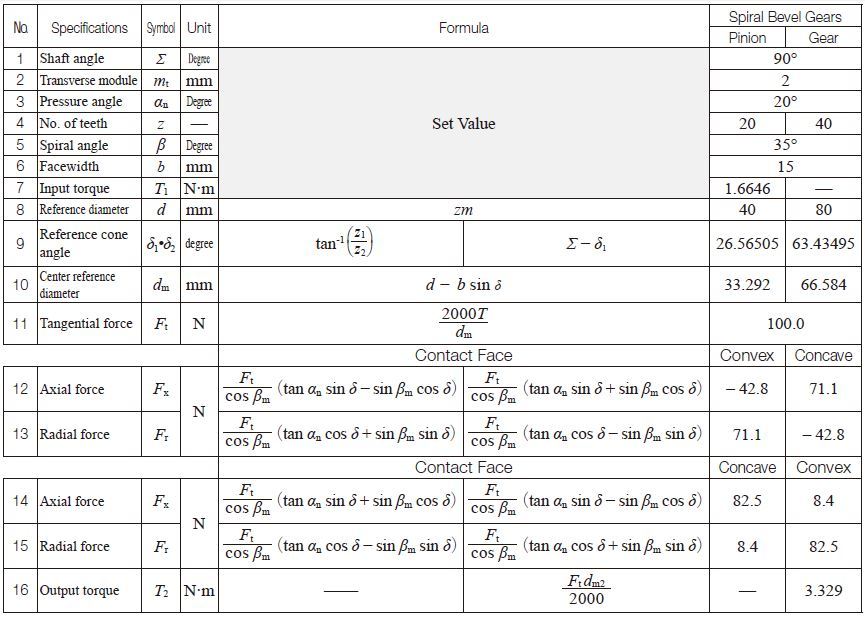

A spiral bevel gear set requires matching of hands. To optimize the performance of any two bevel gears the gears must be positioned together so that they run smoothly without binding andor excessive backlash. The formulas for these values are. F Problem Statement and Solution Problem. Where NA and NB speed of the driver and driven respectively and ZA and ZB Number of teeth on driver and driven respectively. Over 10 7 cycles Impact from motor.

Another Article :

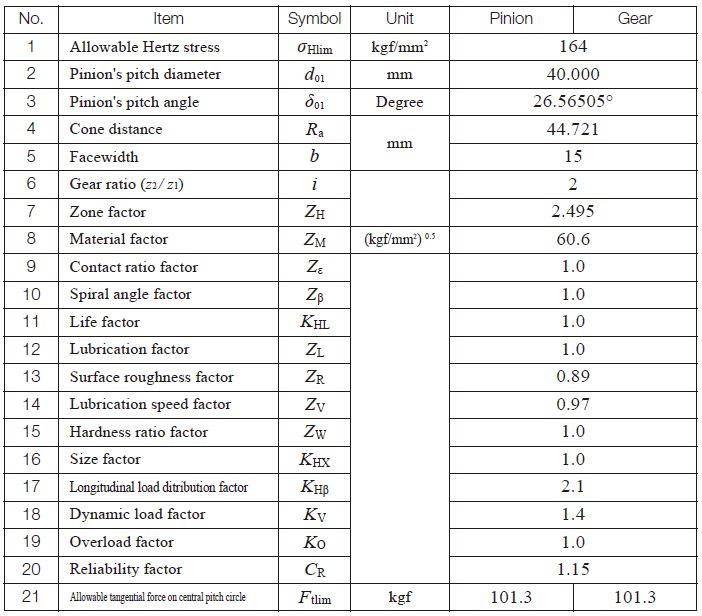

Of teeth of mating gear No. The formulas for these values are. Design procedure for Bevel Gear. 2 γ 1 arctan z 1 z 2 2038 Figure 1 Graphical specification of ring gear blank. Bevel gears whose pitch surfaces are cones are used to drive intersecting axes. Surface Durability Of Bevel Gear Khk Gears.

Formula of bevel gears on bending strengthJGMA403-01 The Lewis formula No. The formulas for these values are. Of teeth of the mating gear of the set Rotational Speed. A spiral bevel gear set requires matching of hands. With bevel gearing the reference diameter d is also known as the pitch diameter. Gear Forces Khk Gear Manufacturer.

Bevel Gear Geometry Page 2 of 4 Tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. 2 γ 1 arctan z 1 z 2 2038 Figure 1 Graphical specification of ring gear blank. Bevel gears are used for the power transmission between non-parallel shafts. Over 10 7 cycles Impact from motor. The further from the intersection of the gear and pinion axes the bigger the tooth cross sections are. Fundamentals Of Bevel Gears Springerlink.

You cannot install bevel gears in the same manner as spur and helical gears and expect them to behave and perform as well. γ 1 γ 2 Σ γ 1 2 In case of a 90 shaft angle the relationship will simplify to. Spur Gear and Assembly Builder - Download DXF SVG Spur Gear design formula for geometry pitch tooth clearance and critical functional data. D 1 z 1 m. Bevel Gear Geometry Page 2 of 4 Tooth shape for bevel gears is determined by scaling spur gear tooth shapes along the face width. Bevel Gear What Is It How Does It Work Types Uses.

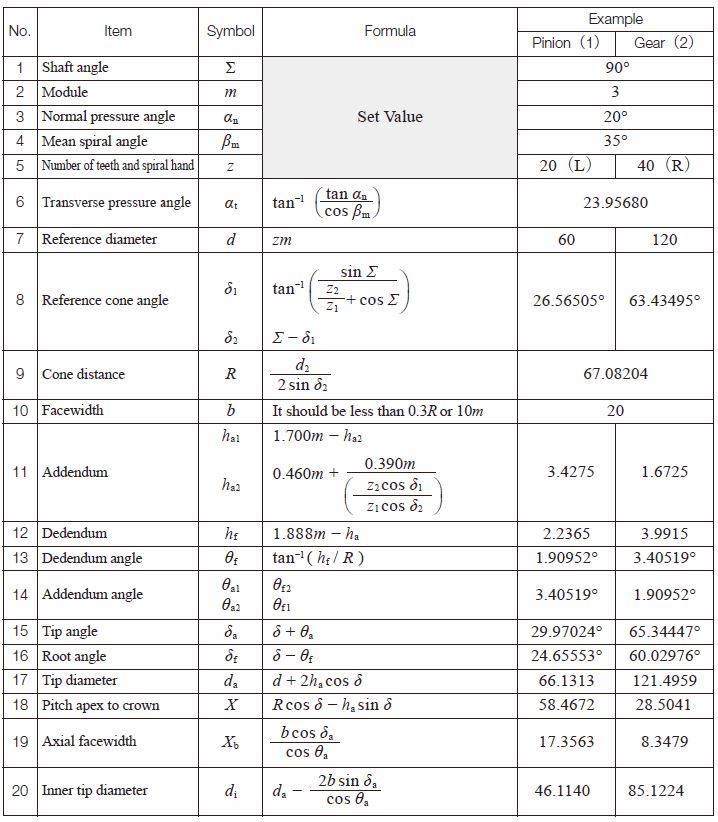

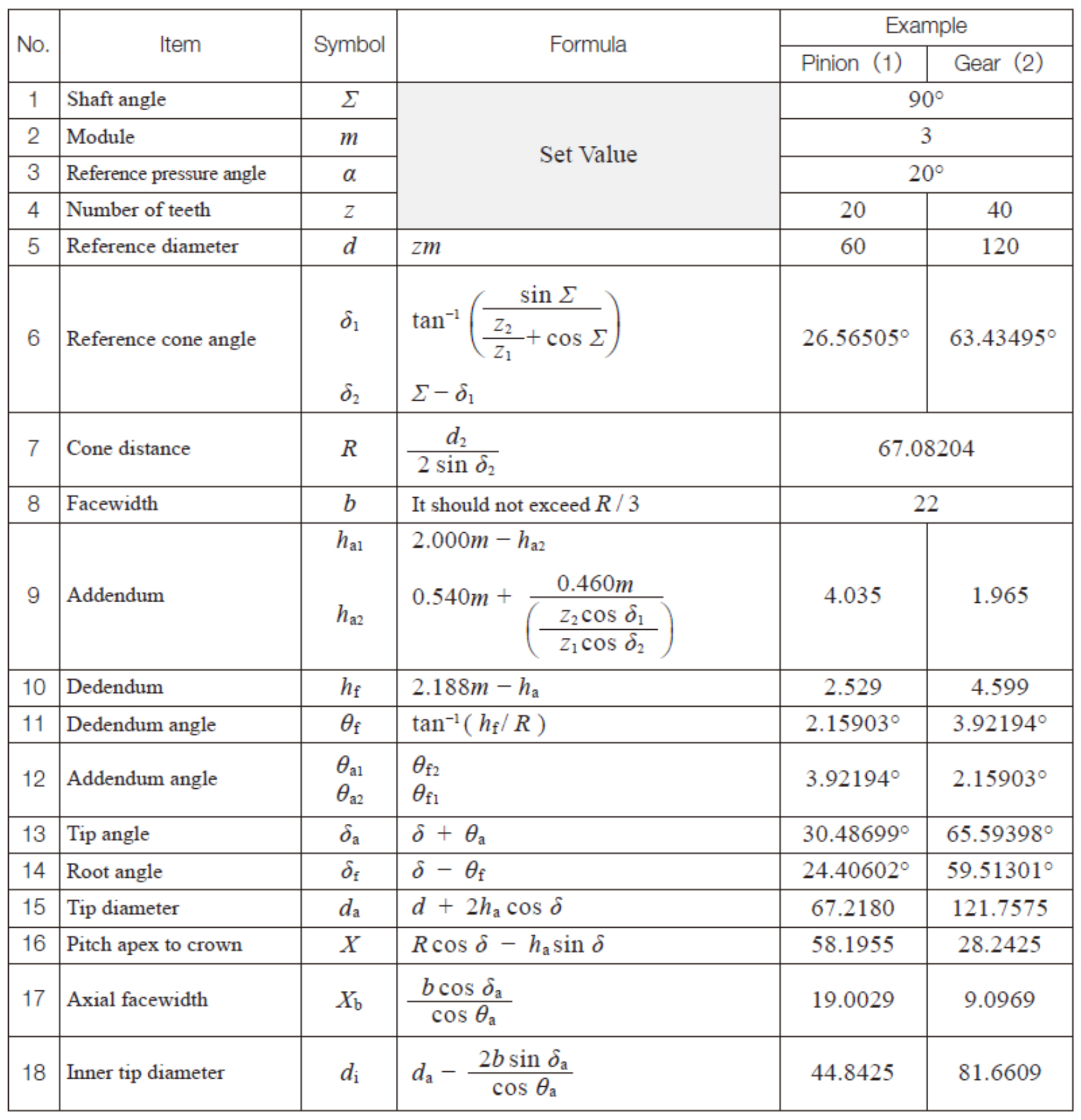

The calculation equations of Table 416 for Gleason straight bevel gears are applicable. The calculation equations of Table 416 for Gleason straight bevel gears are applicable. Should the bevel gear pair not have any axial shift the tooth profile factor YF is simply YF0. Equation 2 is the fundamental equation for the planar involute curve. The complete problem of the bevel gear design with respect to design variables m t b Z 1 P after simplification is Design optimisation of bevel gear pair 371. Engineeringtechnical Info Calculation Of Gear Dimensions.

Equation 2 is the fundamental equation for the planar involute curve. The pitch surface of bevel gears is a cone. Conceptually two meshing bevel gears can be represented by two touching cones referred to as pitch cones or reference cones shown in thick lines on the left image below. Over 10 7 cycles Impact from motor. Of teeth of the mating gear of the set Rotation. Cones Are Not Just For Ice Cream Gear Solutions Magazine Your Resource To The Gear Industry.

Spur Gear Calculator and Geometry Generator - Download DXF SVG csv file. Bevel gears can include straight spiral Zerol hypoid and. Bevel gears are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped. They also should take care again of the rule of hands. Bevel gears are most often mounted on shafts that are 90 degrees apart but can be designed to work at other angles as well. Gear Forces Khk Gear Manufacturer.

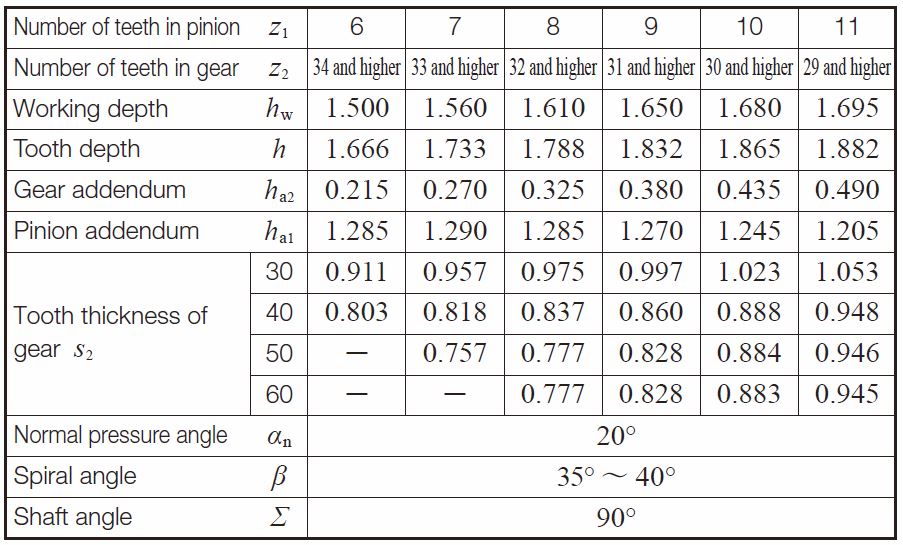

They also should take care again of the rule of hands. Cone-shaped bevel gears are produced for the power transmission between these shafts. Velocity factor for bevel gear is given as here C R v 56 56 v Where v is the pitch line velocity in ms. Calculation of gear ratio i and pitch angle Selection of material. 2 γ 1 arctan z 1 z 2 2038 Figure 1 Graphical specification of ring gear blank. Gleason Spiral Bevel Gears Calculation.

Bevel gears can be also used for only changing the rotation direction of power transmission which are called miter gears. Design procedure for Bevel Gear. 100rpm 600rpm for KMBSG KSBSG KSBZG 100rpm. Computerized Design of Straight Bevel Gears with Optimized Profi les for Forging Molding or. Boston Gear has an excellent document on the formulas and geometry at this link. Iso 23509 2006 En Bevel And Hypoid Gear Geometry.

In the last stage of gear design when gear dimensions are recognized errors are particular and the quality of gear is resolute the dynamic load. Should the bevel gear pair not have any axial shift the tooth profile factor YF is simply YF0. Left and right of a pair must be matched. Finally calculate YF by Equation 1034. Bevel gears are most often mounted on shafts that are 90 degrees apart but can be designed to work at other angles as well. Helical Gear Calculations Crossed Helical Gear Meshes And Bevel Gearing Sdpsi.

Bevel Gear Technology Chapter 2. The equivalent number of teeth zv and the profile shift coefficient x when using Figures 108 and 109 is obtainable from Equation 1035. Of teeth of the mating gear of the set Rotational Speed. Where NA and NB speed of the driver and driven respectively and ZA and ZB Number of teeth on driver and driven respectively. The calculation equations of Table 416 for Gleason straight bevel gears are applicable. Bending Strength Of Bevel Gears Khk Gears.

Where NA and NB speed of the driver and driven respectively and ZA and ZB Number of teeth on driver and driven respectively. Of teeth of mating gear. Of teeth of the mating gear of the set Rotational Speed. 100rpm 600rpm for KMBSG KSBSG KSBZG 100rpm. Inch Units Applicable for Constants Spur Gear Design Calculator. Bevel Gears Technical Information.

Where NA and NB speed of the driver and driven respectively and ZA and ZB Number of teeth on driver and driven respectively. The further from the intersection of the gear and pinion axes the bigger the tooth cross sections are. If the tooth face were to extend all the way to the axes intersection the teeth would approach infinitesimal size. Speed of pinion and gear are Np 500 RPM and Ng 250 RPM respectively. Calculation of gear ratio i and pitch angle. Bending Strength Of Bevel Gears Khk Gears.

D 1 z 1 m. Of teeth of mating gear No. Formula of bevel gears on bending strengthJGMA403-01 The Lewis formula No. F Problem Statement and Solution Problem. If the tooth face were to extend all the way to the axes intersection the teeth would approach infinitesimal size. Surface Durability Of Bevel Gear Khk Gears.

γ 1 γ 2 Σ γ 1 2 In case of a 90 shaft angle the relationship will simplify to. Should the bevel gear pair not have any axial shift the tooth profile factor YF is simply YF0. Bevel gears can be also used for only changing the rotation direction of power transmission which are called miter gears. Over 10 7 cycles Impact from motor. A spiral bevel gear set requires matching of hands. Spiral Bevel Gear Forces Vortarus Technologies Llc.