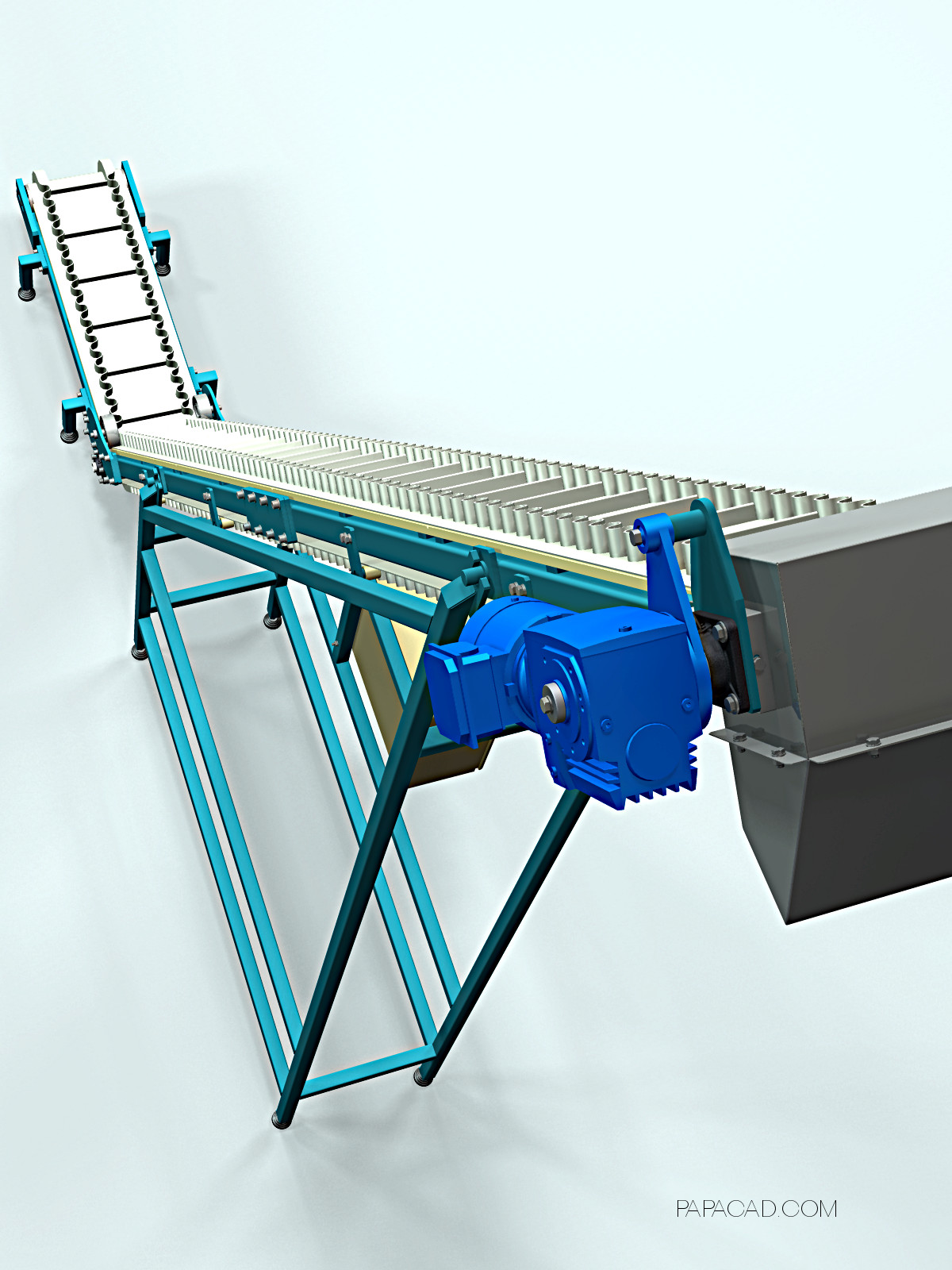

Start up automatic feed supply with the Belt Feeder. Finally specify final design details and additional construction elements for the construction of belts and sprockets to the system. belt feeder design.

Belt Feeder Design, The basic design features of belt and apron feeders is presented. The head load is the amount of pressure put on the belt directly under the hopper opening as a result of the weight of the material resting on the belt. Belt feeder design considerations.

The Development Trend Of Belt Conveyor Conveyor Development Conveyor Belt From pinterest.com

The Development Trend Of Belt Conveyor Conveyor Development Conveyor Belt From pinterest.com

Management with options When it comes to controlling the belt feeding system you have more options. The basic design features of belt and apron feeders is presented. Safe simple and thoroughly economical.

The interface design relies on a variable speed belt to achieve a variable product flow rate.

The head load is the amount of pressure put on the belt directly under the hopper opening as a result of the weight of the material resting on the belt. Bulk solids handling - Vol. Belt feeder and belt conveyor design. The basic design features of belt and apron feeders is presented. As an example a mine in Germany has 6400 mm wide belt feeder for handling lignite at much higher capacity. BELT FEEDERS FOR BULK MATERIALS.

Another Article :

Management with options When it comes to controlling the belt feeding system you have more options. The need for feeders and mass-flow hoppers to be designed as an integral unit to promote uniform feed is emphasised. Gravimetric feeders should be used whenever there is a requirement for close control of material discharge. Starting Load Calculations AE. Because mining processes vary with companies the. Installation And Notes Of Belt Conveyor Anti Rain Cover Conveyor Rain Cover Installation.

Our mechanical and structural engineers have decades of experience in the design and manufacture of custom belt feeders and hoppers to suit a wide range of materials and feed rates. Metso Outotecs belt feeders offering consists of standard capacity BF Series belt feeders and higher capacity models known as BFH belt feeders. Examples include when the feed rate uniformity must be better than 2 or sample collection times must be less than about 30 sec. If the job will stand the additional cost some type of mechanical feeding device may be employed such as a belt feeder apron feeder pan feeder. Maton If this is your first visit be sure to check out the FAQ by clicking the link above. Pin On Diy Conveyor.

Starting Load Calculations AE. A gravimetric feeder should also be used when the. The typical capacity range is up to 1500 m3hour for regularly used belt widths. However belt feeders of higher capacities are also possible. The book provides interesting and useful information about the pressure calculation from hopper however the presented information is in context of belt feeder. Feed Almost Any Type Of Part Easily And Jam Free With The Titan Conveyors Model 350 Pro Feed Parts Conveyor The Customiza Conveyor System Conveyor Conveyors.

Management with options When it comes to controlling the belt feeding system you have more options. How it works Simply open the cover pull back the belt place feed on belt and close the cover and feed will drop out below over a 12 or 24 hour period. Safe simple and thoroughly economical. Belt feeders are often an excellent choice when feeding material from an elongated hopper outlet but can also be used with square or round outlets. Belt feeder design come in a very diverse selection that holds distinct sizes shapes and models to ensure all shoppers. The Development Trend Of Belt Conveyor Conveyor Development Conveyor Belt.

The basic design features of belt and apron feeders is presented. The head load is the amount of pressure put on the belt directly under the hopper opening as a result of the weight of the material resting on the belt. 29 2009 bulk solids handling - Vol. There is no adjustable gate at the front of the hopper to adjust the cross section of product on the belt. Belt feeder design considerations. Pin On Conveyor Belt.

Belt conveyors carry the product which is preferential and less problematic when it comes to the handling of. Belt conveyors are suitable for the conveying of a large range of products - from powders to large bulk solids. This Custom Conveyor System was designed for a manufacturer who needed to load empty trays with parts for an automatic assembly operation. The space-saving design also saves on investment costs. Upon reaching the end of the belt conveyor a pneumatic slide pushed a single tray sideways onto a robotic loading station. Pin By Savona Equipment On Feeders Hoppers Conveyors Gate Conveyor.

In other cases transfer chutes are employed to direct the flow of bulk material from one conveyor belt to another often via a three dimensional path. The space-saving design also saves on investment costs. The basic design features of belt and apron feeders is presented. In other cases transfer chutes are employed to direct the flow of bulk material from one conveyor belt to another often via a three dimensional path. Feeders onto conveyor belts. Pin On Diy Conveyor.

Thesis University of Wollongong 1998. Gravimetric feeders are loss-in-weight and weigh belt. BELT FEEDERS FOR BULK MATERIALS. The head load is the amount of pressure put on the belt directly under the hopper opening as a result of the weight of the material resting on the belt. Therefore the design of the hopper and the belt feeder and the loads on the belt are very much dependent and connected. Portable Belt Conveyor Conveyor System Conveyor Conveyors.

As an example a mine in Germany has 6400 mm wide belt feeder for handling lignite at much higher capacity. The book provides interesting and useful information about the pressure calculation from hopper however the presented information is in context of belt feeder. To solve a conveyor problem certain facts must first be known. How it works Simply open the cover pull back the belt place feed on belt and close the cover and feed will drop out below over a 12 or 24 hour period. Our mechanical and structural engineers have decades of experience in the design and manufacture of custom belt feeders and hoppers to suit a wide range of materials and feed rates. Pin On Diy Conveyor.

Maton If this is your first visit be sure to check out the FAQ by clicking the link above. Examples include when the feed rate uniformity must be better than 2 or sample collection times must be less than about 30 sec. Serving the weigh feeding industry since 1908 MERRICK has a tremendous working knowledge with belt feeders for every application imaginable and we are committed to helping design the feeder that will offer the level of reliable performance accuracy and repeatability your application requires. If the job will stand the additional cost some type of mechanical feeding device may be employed such as a belt feeder apron feeder pan feeder. The Black Star open pit mine at Mt Isa in northern Queensland is an important part of Glencore Xstratas Mount Isa Mines mining operations. Conveyor Belt 3d Model Ad Conveyor Belt Model Conveyor Belt Conveyor Belt.

Therefore the design of the hopper and the belt feeder and the loads on the belt are very much dependent and connected. The Black Star open pit mine at Mt Isa in northern Queensland is an important part of Glencore Xstratas Mount Isa Mines mining operations. The belt feeder design cannot be done unless the pressure values at interface are known. How it works Simply open the cover pull back the belt place feed on belt and close the cover and feed will drop out below over a 12 or 24 hour period. Feeders onto conveyor belts. The Frame Of The Portable Belt Conveyor Conveyor Henan Conveyors.

Management with options When it comes to controlling the belt feeding system you have more options. As an example a mine in Germany has 6400 mm wide belt feeder for handling lignite at much higher capacity. Choose the simple manual solution by pressing one button or get. Flow properties and design procedures for coal storage bins. 29 2009 bulk solids handling - Vol. Stainless Steel Belt Conveyor More Information Please Check Https Sepmachinery Com Material Handling Equipment Conveyors Mechanical Engineering Design.

The essential requirement is to promote uniform feed with. If the job will stand the additional cost some type of mechanical feeding device may be employed such as a belt feeder apron feeder pan feeder. Keep belt clean from food build up and kept as dry as possible. The belt feeder discharge is positive volumetric in nature. How it works Simply open the cover pull back the belt place feed on belt and close the cover and feed will drop out below over a 12 or 24 hour period. Chore Time S 20 Hole Side Belt Nest Boxes Are Designed For Continuous Use With Very Little Maintenance The Eggs Ro Poultry Supplies Poultry House Poultry Farm.

FIAP Belt Feeder Standard is a MUST HAVE for each and every production plant or hobby breeder. Several factors influence belt feeder operation and reliability. Belt feeders are commonly used when material that is either stockpiled or loaded at an uncontrolled rate in a bin or hopper needs to be introduced into the system at a controlled feed rate. Serving the weigh feeding industry since 1908 MERRICK has a tremendous working knowledge with belt feeders for every application imaginable and we are committed to helping design the feeder that will offer the level of reliable performance accuracy and repeatability your application requires. Empty trays were loaded onto a powered Auto-Kinetics heavy-duty belt conveyor. Vibratory Feeder And Portable Belt Conveyor Ordered By Kazakhstan And Philippines Clients Have Been Delivered Conveyor Conveyors Portable.

Feeders onto conveyor belts. Belt conveyors are suitable for the conveying of a large range of products - from powders to large bulk solids. This information is essential for sound conveyor engineering. Management with options When it comes to controlling the belt feeding system you have more options. Our mechanical and structural engineers have decades of experience in the design and manufacture of custom belt feeders and hoppers to suit a wide range of materials and feed rates. Feed Discharge Conveyor For Parts Conveyor Conveyors Conveyor System.