The double piston effect seat design in the API 6D is also called the Double-Isolation-and-Bleed Valve DIB Valve. In the closed position ball is pushed against the seat by the pressure of the fluid from upstream and hence can pressure seal the downstream of the valve. ball check valve design principles.

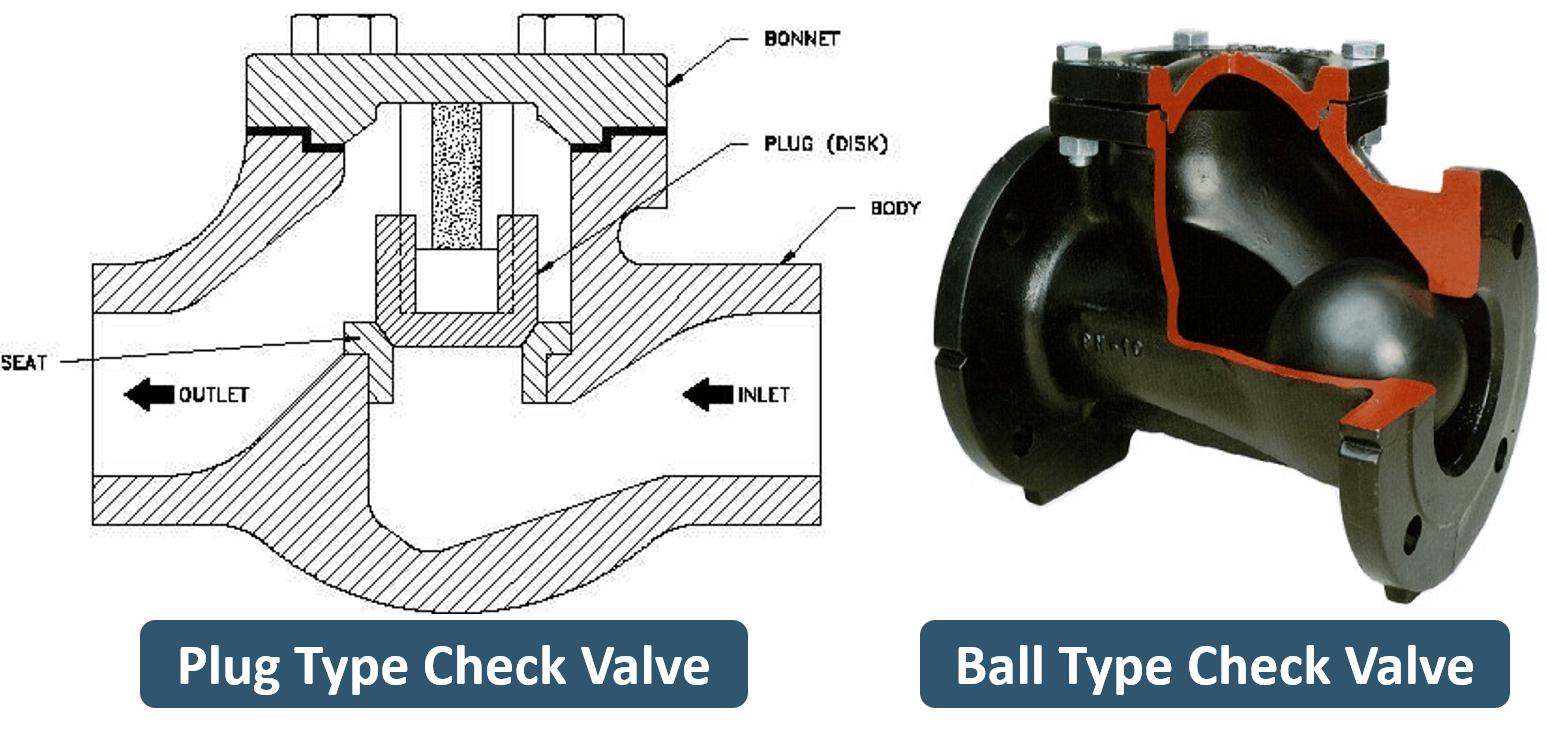

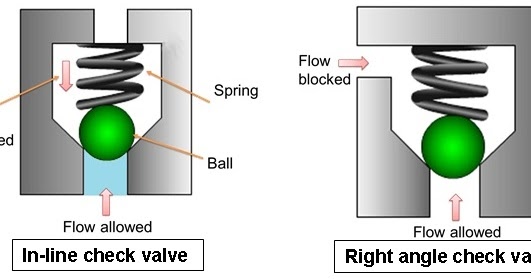

Ball Check Valve Design Principles, In some designs the body itself is split into two sections that bolt together. The interior surface of the main seats of ball check valves are more or less conically-tapered to guide the ball into the seat and form a positive seal when stopping reverse flow. This device requires some pressure to compress the spring and open the valve.

Dimensions Of Class 300 Dual Plate Wafer Check Valves From piping-world.com

Dimensions Of Class 300 Dual Plate Wafer Check Valves From piping-world.com

Ball Check Valves are simple and compact and commonly used on small water or wastewater pumps where economy is important. Fluid flowing to the right will push the ball bearing against the spring and open the valve to permit flow. A Ball Check Valve consists of a threaded or flanged body with internal features that guide a rubbercoated ball in and out of the seat as the flow goes forward and reverse.

In dynamic conditions flow The water pressure exceeds the spring tension.

Specialist in the design and manufacture of high integrity isolation valves. I used Algor to do the CFD and found it necessary to restrict the flow up to 60 GPM into the face of the ball or the flow speed and pressure at the ball face would cause the oil to burn. In a check valve whose disc travel is linear the percent of flow area will be equal to. Ball valve design in which the ball is not rigidly held on its rotational axis is free to float between the seat rings. In the closed position ball is pushed against the seat by the pressure of the fluid from upstream and hence can pressure seal the downstream of the valve. The spring tension forces the plunger into its seat keeping the check valve closed.

Another Article :

Flomatic Corporation is a global manufacturer and distributor of Ball Check Valves. Flomatic Corporation is a global manufacturer and distributor of Ball Check Valves. In a check valve whose disc travel is linear the percent of flow area will be equal to. Ad Severe service high pressure and corrosion resistant material isolation valves. Combination of SPE and DPE A trunnion mounted ball valve with the upstream seat unidirectional and the downstream seat bi-directional blocks the fluid at the downstream seat in both directions while it blocks the fluid on the upstream seat in one direction only. Pin On How Things Work.

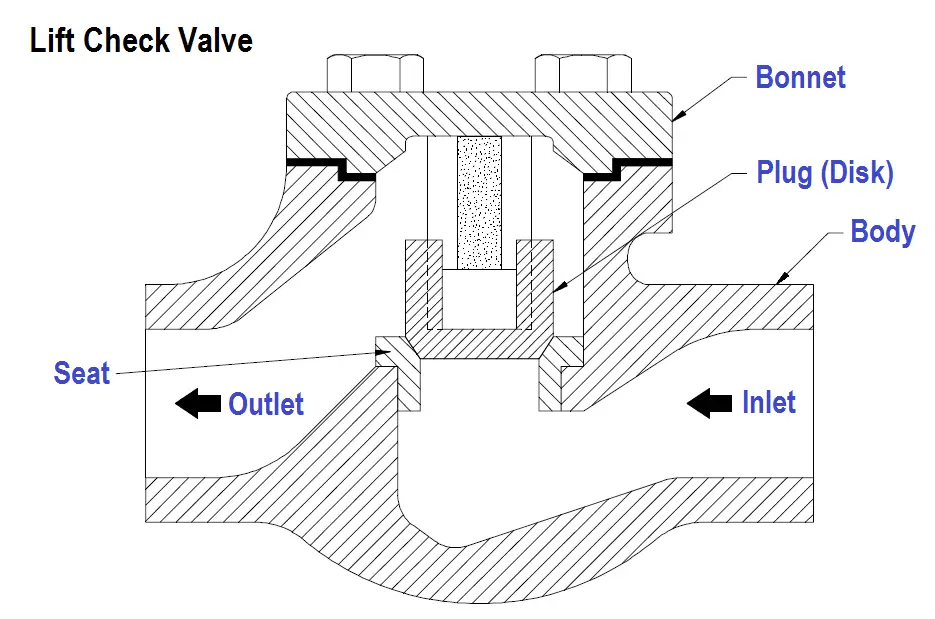

DESIGN FEATURES Ball check non-return valves offering low cracking pressures and drops available with screwed and flanged connectionsAPPLICATIONS Pumping stations for clean sewage water and loaded Viscous fluids TECHNICAL DATA RANGE. Fluid flowing to the right will push the ball bearing against the spring and open the valve to permit flow. It uses a design similar to your check valve but it has a stack of disc springs for pressure and an adjustment screw. Understand valves and control valves working principles for successful operation of your plant and piping systems Understand valve construction details bonnet stem disk seat packing body etc Know the characteristics and applications for each valve type ball plug gate pinch butterfly diaphragm check needle. Ball valve design in which the ball is not rigidly held on its rotational axis is free to float between the seat rings. What Is A Check Valve Learn About Check Valves Types And Parts.

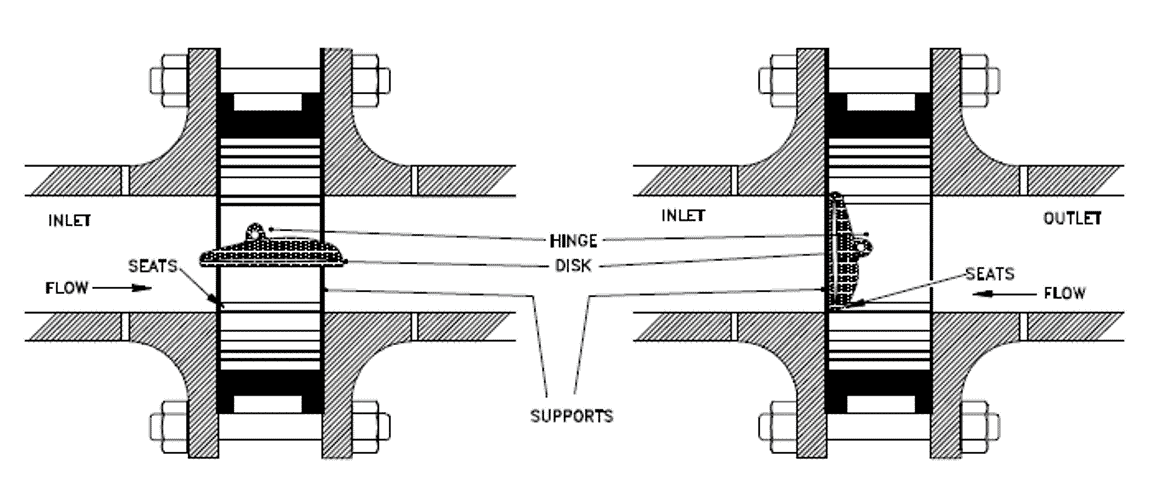

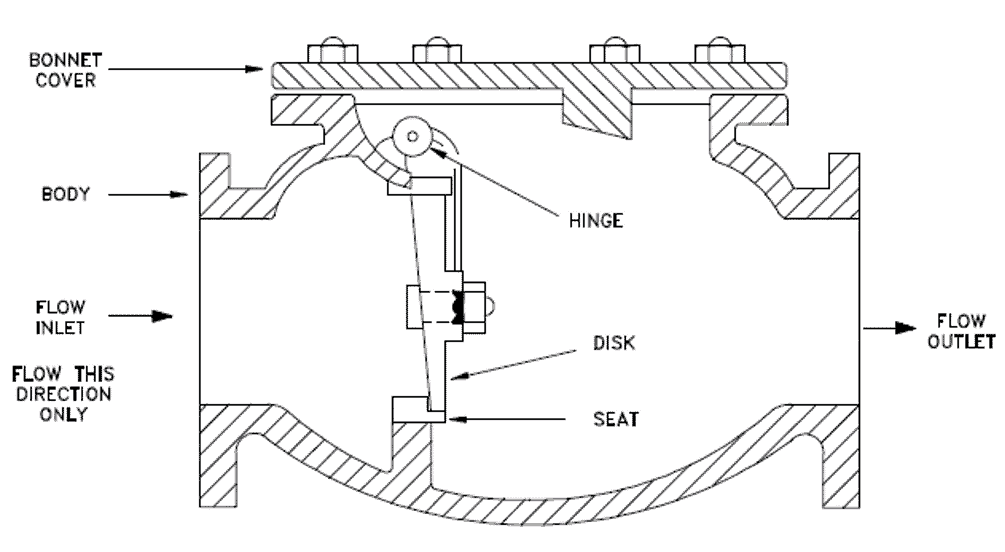

In some designs the body itself is split into two sections that bolt together. Like valve bodies bonnets vary in design. Although manufacturers claim their check valves are leak-free in one direction of flow and allow free flow in the reverse direction a tiny scratch wear mark or imperfection on the poppet or scat will permit some leakage. The ball valve can be closed tightly by 90 degree rotation and small rotational torque. Types of Check Valves. Check Valves And Pumps.

In static conditions no flow The check valve is normally closed. The ball is free to rotate resulting in even wear and a wiping action between the ball and seat. This ball rotates freely when fluid passes through the system which causes a wiping motion and even wear between the ball and seat. Ball Valve structure and working principles. DESIGN FEATURES Ball check non-return valves offering low cracking pressures and drops available with screwed and flanged connectionsAPPLICATIONS Pumping stations for clean sewage water and loaded Viscous fluids TECHNICAL DATA RANGE. What Is A Check Valve Learn About Check Valves Types And Parts.

The interior surface of the main seats of ball check valves are more or less conically-tapered to guide the ball into the seat and form a positive seal when stopping reverse flow. In some ball check valves the ball is spring-loaded to help keep it shut. The interior surface of the main seats of ball check valves are more or less conically-tapered to guide the ball into the seat and form a positive seal when stopping reverse flow. Understand valves and control valves working principles for successful operation of your plant and piping systems Understand valve construction details bonnet stem disk seat packing body etc Know the characteristics and applications for each valve type ball plug gate pinch butterfly diaphragm check needle. Device A consists of a ball bearing retained by a spring. Working Principle Of A Check Valve And Its Types In Hydraulic System Mechanical Engineering Concepts And Principles.

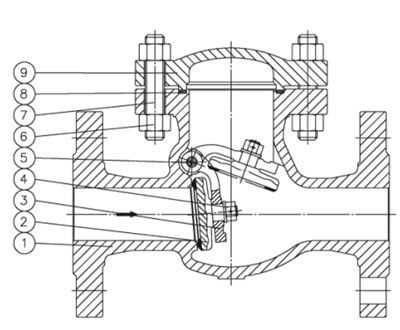

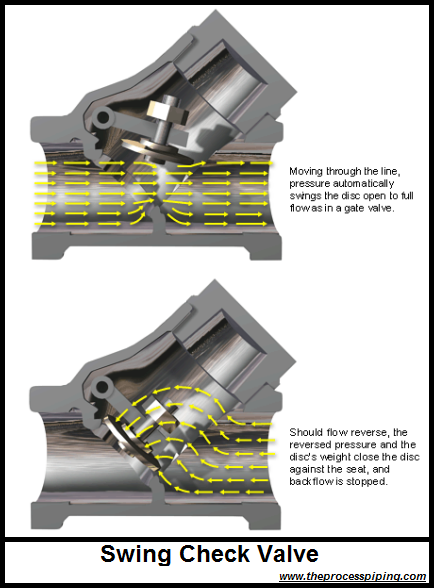

Tech-Taylor valve features Rugged construction and proven abrasion-resistant. I used Algor to do the CFD and found it necessary to restrict the flow up to 60 GPM into the face of the ball or the flow speed and pressure at the ball face would cause the oil to burn. For those designs without a spring reverse flow is required to move the ball toward the seat and create a seal. The double piston effect seat design in the API 6D is also called the Double-Isolation-and-Bleed Valve DIB Valve. The design of AVK ball check valves means minimal maintenance AVK ball check valves are self-cleaning as the ball rotates during operation which eliminates the risk of. Swing Check Valves Api 6d Bs 1868 1873 Asme B16 34 Xinhai.

In dynamic conditions flow The water pressure exceeds the spring tension. Device A consists of a ball bearing retained by a spring. It uses a design similar to your check valve but it has a stack of disc springs for pressure and an adjustment screw. Flomatic Corporation is a global manufacturer and distributor of Ball Check Valves. The ball is free to rotate resulting in even wear and a wiping action between the ball and seat. Introduction To Check Valves The Process Piping.

For those designs without a spring reverse flow is required to move the ball toward the seat and create a seal. The ball is free to rotate resulting in even wear and a wiping action between the ball and seat. DOE FUNDAMENTALS HANDBOOK MECHANICAL SCIENCE Volume 2 of 2. Fluid flowing to the right will push the ball bearing against the spring and open the valve to permit flow. Ad Severe service high pressure and corrosion resistant material isolation valves. Introduction To Check Valves The Process Piping.

Types of Check Valves. The design of AVK ball check valves means minimal maintenance AVK ball check valves are self-cleaning as the ball rotates during operation which eliminates the risk of. This ball rotates freely when fluid passes through the system which causes a wiping motion and even wear between the ball and seat. Ball Check Valves are simple and compact and commonly used on small water or wastewater pumps where economy is important. Ball valve design in which the ball is not rigidly held on its rotational axis is free to float between the seat rings. Ball Check Valve Introduction Valve Introduction Ball.

A check valve utilizing a linear design Silent Check Valve places the disc in-line with the seat. The design of AVK ball check valves means minimal maintenance AVK ball check valves are self-cleaning as the ball rotates during operation which eliminates the risk of. Ad Severe service high pressure and corrosion resistant material isolation valves. The disc travels in a straight line from the open to closed positions. The ball is free to rotate resulting in even wear and a wiping action between the ball and seat. Ball Check Valve Impact Rm.

Flomatic Corporation is a global manufacturer and distributor of Ball Check Valves. Ball valve is mainly constructed of valve body seat ball valve stem handle or other driving device. Ball-type check valves have the least expensive form of construction but as the ball is not guided there is a tendency for leakage to occur. A check valve utilizing a linear design Silent Check Valve places the disc in-line with the seat. It uses a design similar to your check valve but it has a stack of disc springs for pressure and an adjustment screw. Introduction To Check Valves The Process Piping.

The ball valve uses a ball with a round through hole as the opening and closing part. Some bonnets function simply as valve covers while others support valve internals and accessories. The ball valve uses a ball with a round through hole as the opening and closing part. Ball Valve structure and working principles. A Ball Check Valve is a simple and reliable valve with the only moving part to block the reverse flow is a spherical ball. What Is Lift Check Valve Lift Check Valve Parts Lift Check Valve Body.

It uses a design similar to your check valve but it has a stack of disc springs for pressure and an adjustment screw. The Working Principle and Structural Characteristics of Ball Valve. Types of Check Valves. In dynamic conditions flow The water pressure exceeds the spring tension. The spring tension forces the plunger into its seat keeping the check valve closed. Dimensions Of Class 300 Dual Plate Wafer Check Valves.

Understand valves and control valves working principles for successful operation of your plant and piping systems Understand valve construction details bonnet stem disk seat packing body etc Know the characteristics and applications for each valve type ball plug gate pinch butterfly diaphragm check needle. Unlike other valves ball check valves use a spherical ball inside their bodies to help control the flow direction in pipes and systems. Our quality high performance Tech-Taylor valve is a self-actuated two-way ball-check valve specifically designed for isolation of standby pumps. The ball valve uses a ball with a round through hole as the opening and closing part. In dynamic conditions flow The water pressure exceeds the spring tension. What Is A Check Valve Learn About Check Valves Types And Parts.

The Working Principle and Structural Characteristics of Ball Valve. DESIGN FEATURES Ball check non-return valves offering low cracking pressures and drops available with screwed and flanged connectionsAPPLICATIONS Pumping stations for clean sewage water and loaded Viscous fluids TECHNICAL DATA RANGE. The ball valve can be closed tightly by 90 degree rotation and small rotational torque. Ball Check Valves are simple and compact and commonly used on small water or wastewater pumps where economy is important. Combination of SPE and DPE A trunnion mounted ball valve with the upstream seat unidirectional and the downstream seat bi-directional blocks the fluid at the downstream seat in both directions while it blocks the fluid on the upstream seat in one direction only. Miniaturization Of Check Valves Springerlink.