ü Assume Z 1 depending upon the number of stat. A turn needing to trace out circles of different radius. axle design procedure.

Axle Design Procedure, The ends of the axle beam are usually shaped either as yoke or plain surface with drilled hole for connecting the stub axle assembly. For PCCPand 10 yrs. With concrete shoulder use Table 6b and Fig.

Axle Shafts From thecartech.com

Axle Shafts From thecartech.com

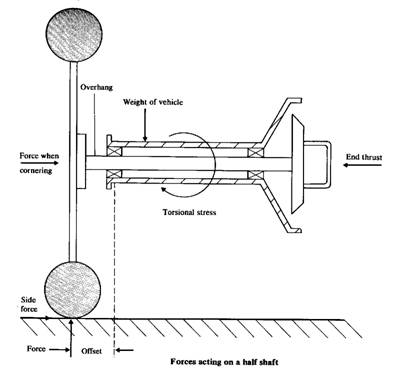

Specific applications like front bucket bund preparation and paddy field demand very rigid axle design. A calculation of the components of moments is done along each one of the three principal directions in order to obtain the resultant moment. Forces to apply on the axle are firstly identified considering masses braking and traction conditions.

ɤ tan-1 z1q 4.

The design construction and maintenance of road pavements involve the management of risks. Which expresses varying axle loads and traffic Once the floor-slab design requirements have been established ie the type of loadings including wall loads and both stationary live and moving live loads the requirements are translated into meaningful design data. Choose a trial slab thickness h. Axle has sufficiently rigidly and strength to transmit the weight of the vehicle from springs to the front wheels. Calculation of Tangential load. For PCCPand 10 yrs.

Another Article :

The Axle Interspinous Fusion System is designed to provide spinal stability for lumbar fusion procedures including the treatment of degenerative disc disease spinal tumors and trauma. The design procedure given by IRC makes use of the CBR value million standard axle concept and vehicle damage factor. Design Traffle P I it - 165 Where. A simple approximation to perfect Ackermann steering geometry may be generated by moving the steering pivot points inward so as to lie on a line drawn between the steering kingpins and the center of the rear axle. F t pv x K 0. Science Fair Projects Wheel And Axle Model Youtube Science Fair Projects Fair Projects Science Fair.

Calculation of diameter factor and lead angle. Once the floor-slab design requirements have been. Bogie designs Today the majority of railway vehicles are equipped with bogies that contain mostly. Divide 56621884 and this will also give a mechanical advantage of 31. This is essential so that for Road Engineers can design a more robust road network without going into frequent maintenance due to poorly designed roads and pavements. Axle Shafts.

Which expresses varying axle loads and traffic Once the floor-slab design requirements have been established ie the type of loadings including wall loads and both stationary live and moving live loads the requirements are translated into meaningful design data. This is essential so that for Road Engineers can design a more robust road network without going into frequent maintenance due to poorly designed roads and pavements. With concrete shoulder use Table 6b and Fig. If using cambered axle locate and mark the upper camber line top dead centre of the axles. 2-axle car design principles are used mainly for European freight cars shunting locomotives and for sections of articulated cars such as low-floor light rail vehicles or tramways. Our Open Minded Technical Team Has Made A Great Contribution To The Company Operation And Development We Strictl Trailer Axles Landing Gear Trailer Suspension.

B Divide n i by N i to determine fatigue damage factor d i. D Divide n i by N i to determine erosion damage factor d i. Calculation of diameter factor and lead angle. For PCCPand 10 yrs. The design construction and maintenance of road pavements involve the management of risks. Pin By David Kenworthy On Motor Truck Chevy Trucks Sales Brochures 1968 Chevy Truck.

The axle should be able to pivot - 6 degrees from the horizontal. The step-by-step design procedure is as follows. D Divide n i by N i to determine erosion damage factor d i. Front axle endures the most in tractor aggregate. Outside of these particular areas the Bison Pullers allowed our team free reigns to the overall design of the front axle. Axle Shafts.

Sum fatigue and erosion damage factors over all of the axle load classes. Once the floor-slab design requirements have been. Work with students to calculate the circumference of the wheel 5662 cm and the circumference of the axle 1884 cm. The ends of the axle beam are usually shaped either as yoke or plain surface with drilled hole for connecting the stub axle assembly. C Determine N i for erosion failure. Drive Axles An Overview Sciencedirect Topics.

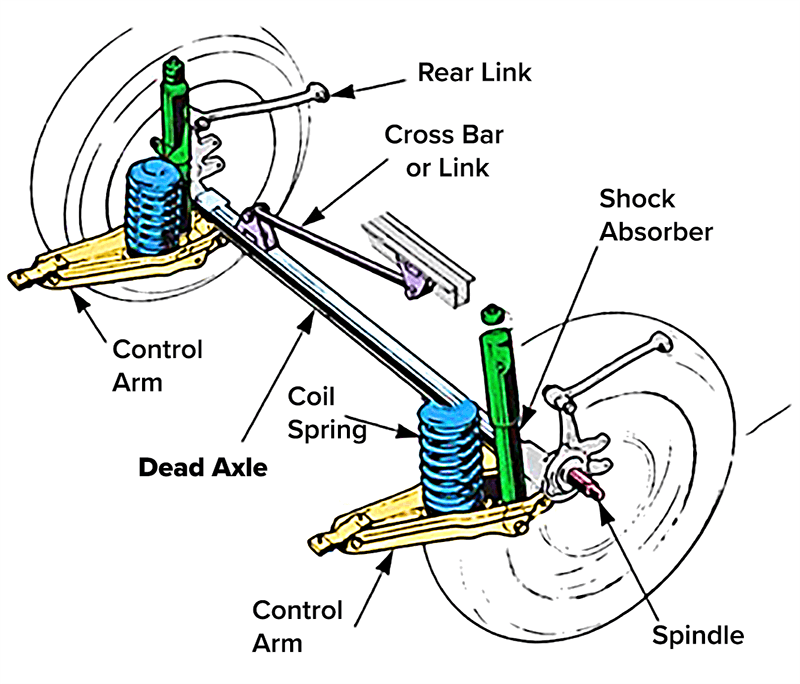

DESIGN PROCEDURE FOR WORM GEAR. Designand optimization of suspension system. C Determine N i for erosion failure. Volume in terms of relative severity. A turn needing to trace out circles of different radius. Car Suspension Basics How To Design Tips Free.

The axle loads are multiplied by the load safety factor for Column 2. Designand optimization of suspension system. For each axle load class. Outside of these particular areas the Bison Pullers allowed our team free reigns to the overall design of the front axle. Design of Track Sections The design of axle counter sections should be based on the operational needs for train movements and not on requirements for sweep trains during reset. Komatsu Wa900 3 Wheel Loader Field Assembly Manual 50001 And Up Gen00019 00 Washer Fluid Komatsu Manual.

D Divide n i by N i to determine erosion damage factor d i. Designand optimization of suspension system. DESIGN PROCEDURE FOR WORM GEAR. Which expresses varying axle loads and traffic Once the floor-slab design requirements have been established ie the type of loadings including wall loads and both stationary live and moving live loads the requirements are translated into meaningful design data. Briefly the design procedure can be summarized in steps as follows. Axles An Overview Sciencedirect Topics.

Calculation of diameter factor and lead angle. Choose a trial slab thickness h. Q d1m x. Specific applications like front bucket bund preparation and paddy field demand very rigid axle design. Design of front axle is more important and critical in application stand point. Rotor With Hub And Bearing Diagrams Bear Mechanical Engineering Diagram.

However the position of axle counter heads for point sections should be close to the clearance point of the diverging paths of the point where possible. Design of front axle is more important and critical in application stand point. The step-by-step design procedure is as follows. If not given assume q 11. Design of Track Sections The design of axle counter sections should be based on the operational needs for train movements and not on requirements for sweep trains during reset. Custom Procedures Lockout Tagout Custom Computer Aided Drafting.

Designand optimization of suspension system. Next have students disconnect the wheel axle from the structure. Bogie designs Today the majority of railway vehicles are equipped with bogies that contain mostly. This means that the wheel is three times larger than the axle. Which expresses varying axle loads and traffic Once the floor-slab design requirements have been established ie the type of loadings including wall loads and both stationary live and moving live loads the requirements are translated into meaningful design data. Fundamentals Of Machine Design And Design Philosophy Machine Design Fundamental Design.

Choose a trial slab thickness h. The axle loads are multiplied by the load safety factor for Column 2. Which expresses varying axle loads and traffic Once the floor-slab design requirements have been established ie the type of loadings including wall loads and both stationary live and moving live loads the requirements are translated into meaningful design data. The ends of the axle beam are shaped suitably to assemble the stub axle. Axle has sufficiently rigidly and strength to transmit the weight of the vehicle from springs to the front wheels. How To Measure For A Straight Axle Spring Rat Rods Truck Rat Rod Rat Rod Pickup.

The first design goal and likely most important goal set by the Bison Pullers was the weight. Design Traffle P I it - 165 Where. Design of front axle is more important and critical in application stand point. Choose a trial slab thickness h. Design procedure the following are considered to be minimum practical thicknesses that are to be applied to each pavement layer. What Is A Drive Axle How Drive Axles Work.

Engineering Road Note 9 outlines the procedure to be used for the design of road pavements that have a bituminous or concrete wearing course and are under the control of the Commissioner of Main Roads Western Australia. Once the floor-slab design requirements have been. Designand optimization of suspension system. Review axle manufacturer s specifications as preheating the axle connection components may be required. Divide 56621884 and this will also give a mechanical advantage of 31. Car Suspension Basics How To Design Tips Free.