WE Wearing and Shoulder Wearing Course. You can get more information from the Asphalt Institutes MS-2 Asphalt Mix Design Methods 7th edition book. asphalt wearing course mix design.

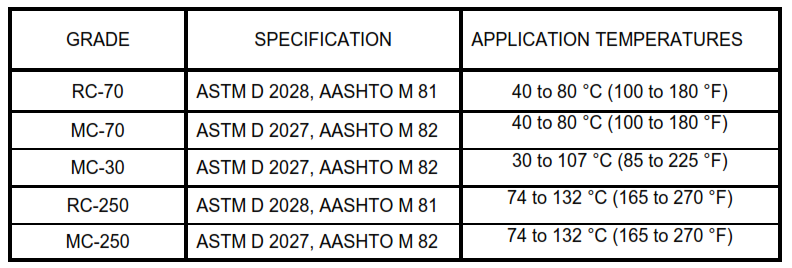

Asphalt Wearing Course Mix Design, INTRODUCTION Many empirical and semi empirical design procedures for hot mix asphalt HMA design have been devised which first attempted to evaluate various properties of bituminous mixtures. SP Gyratory Mixture Design LV Marshall Mixture Design Low Volume 50 blow MV Marshall Mixture Design Medium Volume 50 blow SM Gyratory Mixture Design for Stone Matrix Asphalt SMA 2 The third and fourth letters indicate the course. 3092 Materials follows 4092.

Aggregate Mixing Ratio For Wearing Course Download Table From researchgate.net

Aggregate Mixing Ratio For Wearing Course Download Table From researchgate.net

Aggregate asphalt binders and airGenerally. Resistance to permanent deformation. The manual is considered the basis for mix design.

The five traffic levels are as shown in Table 334-1.

Aggregate asphalt binders and airGenerally. The Asphalt Institute strongly endorses the use of RAP in asphalt mixtures. Some of the more widely known of these design procedures are the Marshall Hveem. Mastic asphalt is an intimate homogenous mixture of selected well-graded aggregate filler bitumen. In the European market it has become possible to get European Conformity CE markings for bituminous mixes indicating that a. In Turkey modified bitumen and aggregates produced.

Another Article :

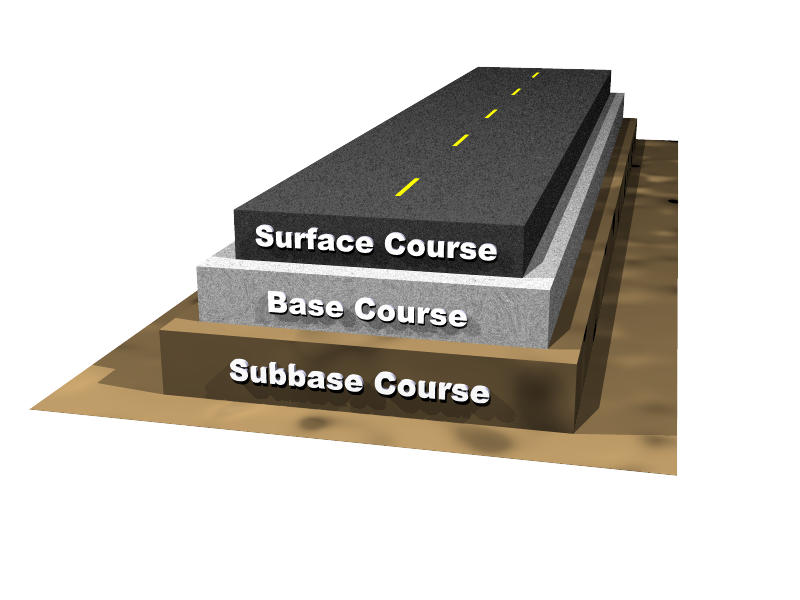

This work shall consist of constructing a single layer of mastic asphalt wearing course for road and bridge decks. The design of asphalt paving mix as with the design of other engineering materials is largely a matter of selecting and proportioning constituent materials to obtain the desired properties in the finished pavement structure. The manual is considered the basis for mix design. CHAPTER 11BONDED WEARING COURSE November 21 2007 112 DESIGN AND SPECIFICATIONS 1121 Hot Mix Asphalt This section provides an overview of materials used in the construction of bonded wearing courses. 1 The first two letters indicate the mixture design type. Asphalt Concrete Base Acb Pavement Interactive.

This is the most often used means for salvaging and extending the service life of older deteriorating pavements. UTWC-10 was used as an example to illustrate the application of the CAVF method in the gradation design of asphalt mixture of ultra-thin. HOT MIX ASPHALT RESURFACING Resurfacing is the placing of one or more courses of hot mix asphalt over an existing hard surface pavement. This is the most often used means for salvaging and extending the service life of older deteriorating pavements. Almost all state highway departments now allow the use of RAP. Scasphalt Org.

Some of the more widely known of these design procedures are the Marshall Hveem. Four porous asphalt mix designs with porosity varying from 12 to 25 were tested to study the effect of porosity level. They incorporate crush stone or gravel and anywhere from 5 to 10 percent asphalt binder. The major parameter in design of hot mix asphalt HMA for it to be both stable and durable is to find out the optimum. A specialised Size 10mm or 14mm asphalt wearing course or Size 20mm structural base course with a high binder content and crumb rubber incorporated into the mix for use in heavily trafficked pavements LTCRA A Size 7mm 10mm or 14mm asphalt wearing course with crumb rubber incorporated into the mix for use in light trafficked pavements. Asphalt Layer An Overview Sciencedirect Topics.

A specialised Size 10mm or 14mm asphalt wearing course or Size 20mm structural base course with a high binder content and crumb rubber incorporated into the mix for use in heavily trafficked pavements LTCRA A Size 7mm 10mm or 14mm asphalt wearing course with crumb rubber incorporated into the mix for use in light trafficked pavements. Bonded wearing courses are constructed using polymer-modified or rubber binders and gap-graded or open-graded aggregates. ADVANTAGES OF HOT MIX ASPHALT 1. The finished surface of asphalt wearing course shall be of uniform appearance free of dragged areas cracks open textured patches and roller marks. Asphalt mix design manual for South Africa provisional working document November 2014. Construction Procedure Of Asphalt Concrete Paving And Roadways Paktechpoint.

Some of the more widely known of these design procedures are the Marshall Hveem. Superpave Asphalt Mix Design HMA Base Course 3091 Description - This work is the standard construction of plant mixed Hot-Mix Asphalt HMA base course on a prepared surface using a volumetric mixture design developed with the Superpave Gyratory Compactor. This paper has demonstrated a laboratory procedure to determine the sound absorption characteristics of porous asphalt pavement wearing course mix designs and estimate their contributions to tire-pavement noise reduction. Surface Course means an HMA wearing course of any flexible or composite pavement. The specifying agency or owner will set the limit for RAP content. Hma Pavement Pavement Interactive.

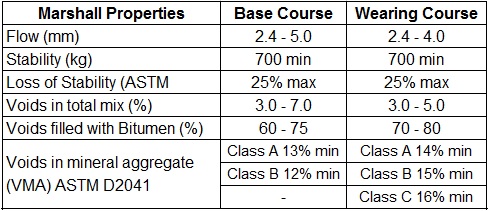

The desirable properties of Asphalt mixes are. The Marshall mix design method can use any suitable method for estimating optimum asphalt content and usually relies on local procedures or experience. CHAPTER 11BONDED WEARING COURSE November 21 2007 112 DESIGN AND SPECIFICATIONS 1121 Hot Mix Asphalt This section provides an overview of materials used in the construction of bonded wearing courses. Abstract - Hot mix asphalt wearing course in a flexible road pavement is the most important and critical layer in a pavement structure and must be of high quality. Vertical Surface means all edges of concrete curbs catch basins and other appurtenances longitudinal. Aggregate Mixing Ratio For Wearing Course Download Table.

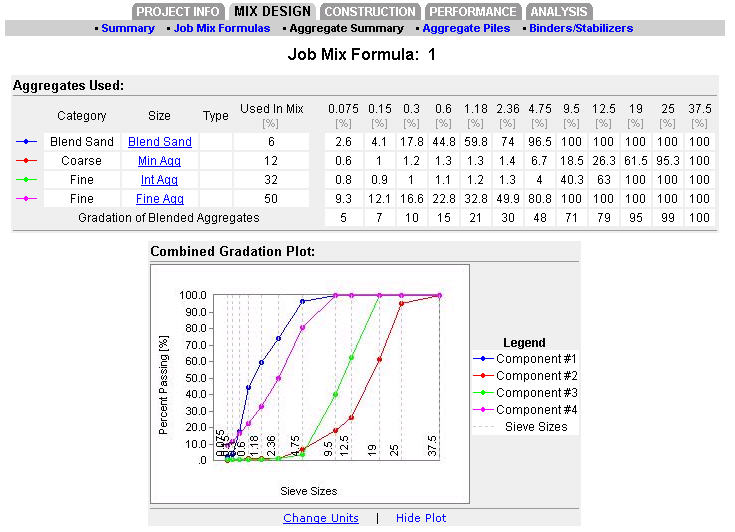

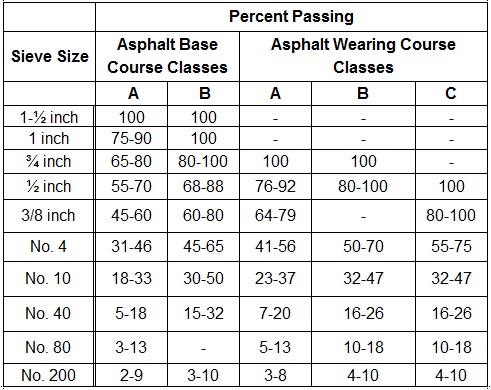

In Turkey modified bitumen and aggregates produced. Restricted zone Superpave gradation wearing course. 3092 Materials follows 4092. Mastic Asphalt Mix Design For Wearing Course. UTWC-10 was used as an example to illustrate the application of the CAVF method in the gradation design of asphalt mixture of ultra-thin. Particle Size Distribution And The Job Mix Formula For The Hot Mix Download Table.

CHAPTER 11BONDED WEARING COURSE November 21 2007 112 DESIGN AND SPECIFICATIONS 1121 Hot Mix Asphalt This section provides an overview of materials used in the construction of bonded wearing courses. Almost all state highway departments now allow the use of RAP. Aggregate asphalt binders and airGenerally. INTRODUCTION Many empirical and semi empirical design procedures for hot mix asphalt HMA design have been devised which first attempted to evaluate various properties of bituminous mixtures. The design of asphalt paving mix as with the design of other engineering materials is largely a matter of selecting and proportioning constituent materials to obtain the desired properties in the finished pavement structure. Construction Procedure Of Asphalt Concrete Paving And Roadways Paktechpoint.

Sample Asphalt Binder Contents Based on the results of the optimum asphalt binder content estimate samples are typically prepared at 05 percent by weight of mix increments with at least two samples above the. Sample Asphalt Binder Contents Based on the results of the optimum asphalt binder content estimate samples are typically prepared at 05 percent by weight of mix increments with at least two samples above the. The requirements for Type SP Asphalt Concrete mixtures are based on the design traffic level of the project expressed in 18000 pound Equivalent Single Axle Loads ESALs. Mix design considerations for asphalt wearing courses with high reclaimed asphalt content. The Asphalt Institute strongly endorses the use of RAP in asphalt mixtures. Reclaimed Asphalt Pavement User Guideline Asphalt Concrete Hot Recycling User Guidelines For Waste And Byproduct Materials In Pavement Construction Fhwa Rd 97 148.

The mix should not distort or be displaced when subjected to traffic. ADVANTAGES OF HOT MIX ASPHALT 1. Table 334-1 Superpave Traffic Levels Traffic Level Traffic Level 1x10. SP Gyratory Mixture Design LV Marshall Mixture Design Low Volume 50 blow MV Marshall Mixture Design Medium Volume 50 blow SM Gyratory Mixture Design for Stone Matrix Asphalt SMA 2 The third and fourth letters indicate the course. The finished surface of asphalt wearing course shall be of uniform appearance free of dragged areas cracks open textured patches and roller marks. Mix Design Of The Hrs Wc Mixture Download Table.

Aggregate asphalt binders and airGenerally. The specifying agency or owner will set the limit for RAP content. RAP has a history of positive performance. Bonded wearing courses are constructed using polymer-modified or rubber binders and gap-graded or open-graded aggregates. The design of asphalt paving mix as with the design of other engineering materials is largely a matter of selecting and proportioning constituent materials to obtain the desired properties in the finished pavement structure. Aggregate Mixing Ratio For Wearing Course Download Table.

The manual is considered the basis for mix design. The manual is considered the basis for mix design. 1 The first two letters indicate the mixture design type. HMA mixture is made of three materials. SP Gyratory Mixture Design LV Marshall Mixture Design Low Volume 50 blow MV Marshall Mixture Design Medium Volume 50 blow SM Gyratory Mixture Design for Stone Matrix Asphalt SMA 2 The third and fourth letters indicate the course. Superpave Mix Design Pavement Interactive.

The major parameter in design of hot mix asphalt HMA for it to be both stable and durable is to find out the optimum. RAP has a history of positive performance. Four porous asphalt mix designs with porosity varying from 12 to 25 were tested to study the effect of porosity level. Asphalt concrete wearing course mixture. The desirable properties of Asphalt mixes are. Asphalt Concrete Receiving Placement And Testing Inspection Wearing And Binder Course.

The five traffic levels are as shown in Table 334-1. Superpave Asphalt Mix Design HMA Base Course 3091 Description - This work is the standard construction of plant mixed Hot-Mix Asphalt HMA base course on a prepared surface using a volumetric mixture design developed with the Superpave Gyratory Compactor. Mix design considerations for asphalt wearing courses with high reclaimed asphalt content. Asphalt mix design manual for South Africa provisional working document November 2014. The desirable properties of Asphalt mixes are. Procedure For Asphalt Concrete Paving And Road Activities Civil Paktechpoint.

UTWC-10 was used as an example to illustrate the application of the CAVF method in the gradation design of asphalt mixture of ultra-thin. Based on the porosity the Course Aggregate Void Filling CAVF method was used to design three asphalt mixtures of ultra-thin wearing course with different porosities and UTWC-10 was compared with OGFC-7 and Novachip-B. HMA mixture is made of three materials. Open-graded mixes offer good wearing base or intermediate courses. Superpave Asphalt Mix Design HMA Base Course 3091 Description - This work is the standard construction of plant mixed Hot-Mix Asphalt HMA base course on a prepared surface using a volumetric mixture design developed with the Superpave Gyratory Compactor. Asphalt Concrete Receiving Placement And Testing Inspection Wearing And Binder Course.