Material Elastic Modulus And Poisson Ratio Data Module. B31 in March 1926 at the request of the American Society of Mechanical Engineers and with that Society as sole sponsor. asme b31 8 design factor.

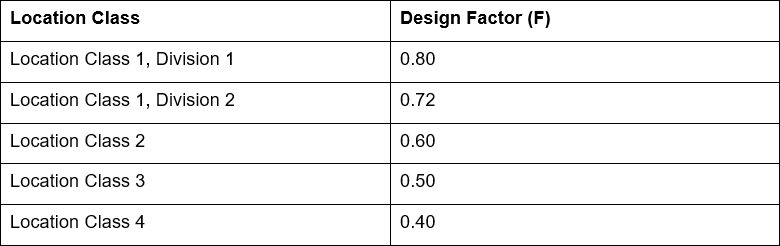

Asme B31 8 Design Factor, T design t design Design Temperature 60-120 Corrosion Allowance None Design Location Class Class 4. Rumus wall thickness menurut B318 dinyatakan sebagai berikut. For location class 4 the design factor is 04 for all facility.

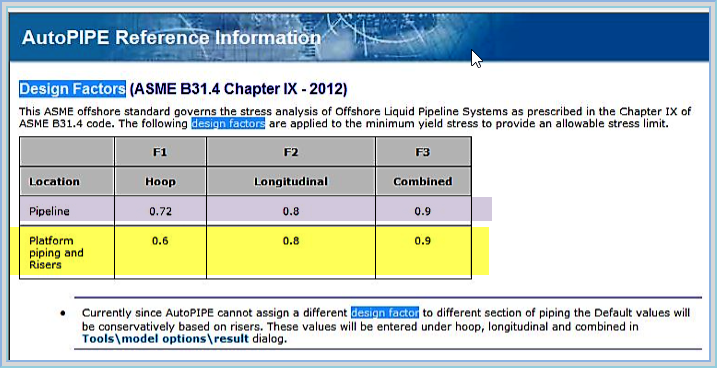

01 Where Are The Design Factors Referenced In Autopipe Help Coming From In Asme B31 4 Chapter Ix Offshore Code Autopipe Wiki Autopipe Bentley Communities From communities.bentley.com

01 Where Are The Design Factors Referenced In Autopipe Help Coming From In Asme B31 4 Chapter Ix Offshore Code Autopipe Wiki Autopipe Bentley Communities From communities.bentley.com

But ASME B314 deals with pipelines transporting liquids and slurries whereas ASME B318 deals with gas transmission and distribution. B31 in March 1926 at the request of the American Society of Mechanical Engineers and with that Society as sole sponsor. Material Elastic Modulus And Poisson Ratio Data Module.

Location class design factor for ASME B318.

ASME has been defining piping safety since 1922. The maximum value is 08 not 10 and the lowest value is 04. B318 makes no distinction between socket welds with undercut and socket welds without undercut. T design t design Design Temperature 60-120 Corrosion Allowance None Design Location Class Class 4. Please note the design temperature is 250 F 120 C so this is acceptable for using ASME B314 code. Design Factor F Longitudinal Factor E MAWP Temperature Derating Factor T.

Another Article :

0246 inches PASS Design Pressure 1250 2 St FET ASME B 318 NA inch 42000 inch inch Sch. DNVGL Design Factor Data Module. Class 1 Division 2 - A Location Class 1 where the design factor of the pipe is equal to or less than 072 but equal to or less than 080 and which has been hydrostatically tested to 11 times the maximum operating pressure. Material Heat Transfer And Thermal Capacity Data Module. S Psig. Asme B31 8 Pdf Pipe Fluid Conveyance Gas Technologies.

This article is about DOWNLOAD ASME B318 GAS TRANSMISSION AND DISTRIBUTION PIPING SYSTEMS Piping System Components and Fabrication Details ASME Standards. We serve all types of industries across Canada globally. - Steel Pipe Temperature Derating Factor. March 22 2011 File. For onshore pipelines and offshore platform piping the allowable pressure is the maximum allowable design pressure for the pipeline location class and facility type. A Comparison Of Inherent Risk Levels In Asme B31 8 And Uk Gas Pipeline Design Codes Semantic Scholar.

DNVGL Design Factor Data Module. An interpretation of this requirement. B31 in March 1926 at the request of the American Society of Mechanical Engineers and with that Society as sole sponsor. Location class design factor for ASME B318. ASME B318 Gas Pipeline Design Pressure Calculator Module Calculate ASME B318 gas pipeline maximum allowable design pressure from allowable stress and pressure design wall thickness. Design Engineering Of Crude Oil And Natural Gas Pipelines.

We serve all types of industries across Canada globally. Modifications to the flexibility factor and Stress Intensification Factor SIF using B318 Modifications to the flexibility factor and SIF of bends resulting from flange d ends are permitted by the code. 08 072 06 05 04. This equation is used in ASME B318 - Gas Transmission and Distribtuion Piping Systems. - Piping Design Factor. Pipe Wall Thickness Calculation As Per Asme B31 8 Engineering Blog.

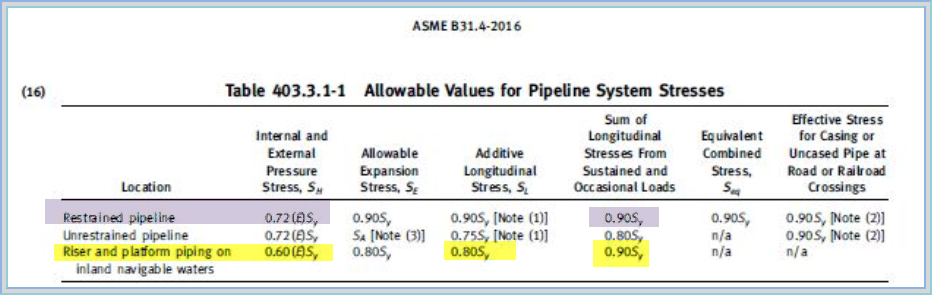

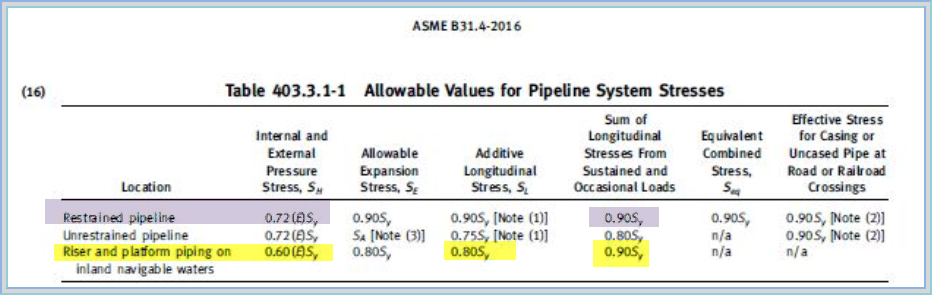

ASME B318 INTERPRETATIONS VOLUME 16 Interpretation. That value of 072 is a factor for B314 Chapter IX - Offshore piping. Kindly note that the exceptions to the design factors are shown in table 84116-2 of ASME B318. Calculate socket welds using B318. A Hoop Stress page 104 Sh F1ST F1 hoop stress design factor from Table A84222-1 S specified minimum yield strength psi MPa Sh hoop stress psi MPa. Pipe Wall Thickness Calculation As Per Asme B31 8 Engineering Blog.

ASME B318 INTERPRETATIONS VOLUME 16 Interpretation. B31 in March 1926 at the request of the American Society of Mechanical Engineers and with that Society as sole sponsor. We serve all types of industries across Canada globally. Please note the design temperature is 250 F 120 C so this is acceptable for using ASME B314 code. In the hydro test table for B318 piping code the column F for maximun design factor has values ranging from 04 to 08 depending on whether its class 1 2 3 or 4. Table 2 From A Comparison Of Inherent Risk Levels In Asme B31 8 And Uk Gas Pipeline Design Codes Semantic Scholar.

Not exceed 75 of the allowable stress in the hot condition. - Steel Pipe Temperature Derating Factor. Rumus wall thickness menurut B318 dinyatakan sebagai berikut. These exceptions include compressor station piping pipelines on bridges pipeline crossing roads etc. See table 841116A at ASME B318 Code. Gas Pipeline Design Focus On Wall Thickness Calculation Epcm Holdings.

ASME B318 Gas Pipeline Design Pressure Calculator Module Calculate ASME B318 gas pipeline maximum allowable design pressure from allowable stress and pressure design wall thickness. ASME B314 vs ASME B318. - Steel Pipe Temperature Derating Factor. For on-shore piping B314 that field for F indicates the amount the pipeline may be considered under complete axial restraint. ASME B315 Refrigeration Piping Design Factor Calculator Module. 01 Where Are The Design Factors Referenced In Autopipe Help Coming From In Asme B31 4 Chapter Ix Offshore Code Autopipe Wiki Autopipe Bentley Communities.

Please note the design temperature is 250 F 120 C so this is acceptable for using ASME B314 code. But ASME B314 deals with pipelines transporting liquids and slurries whereas ASME B318 deals with gas transmission and distribution. Kindly note that the exceptions to the design factors are shown in table 84116-2 of ASME B318. ASME B313 Process Piping Design Factor Data Module. The maximum value is 08 not 10 and the lowest value is 04. 01 Where Are The Design Factors Referenced In Autopipe Help Coming From In Asme B31 4 Chapter Ix Offshore Code Autopipe Wiki Autopipe Bentley Communities.

March 22 2011 File. Not exceed 75 of the allowable stress in the hot condition. The nominal wall thickness is determined by the following formula from ASME B318 para 8411. What are those numbers multiplied by in other words how are thos numbers used. ASME B315 Refrigeration Piping Design Factor Calculator Module. Pipe Wall Thickness Calculation As Per Asme B31 8 Engineering Blog.

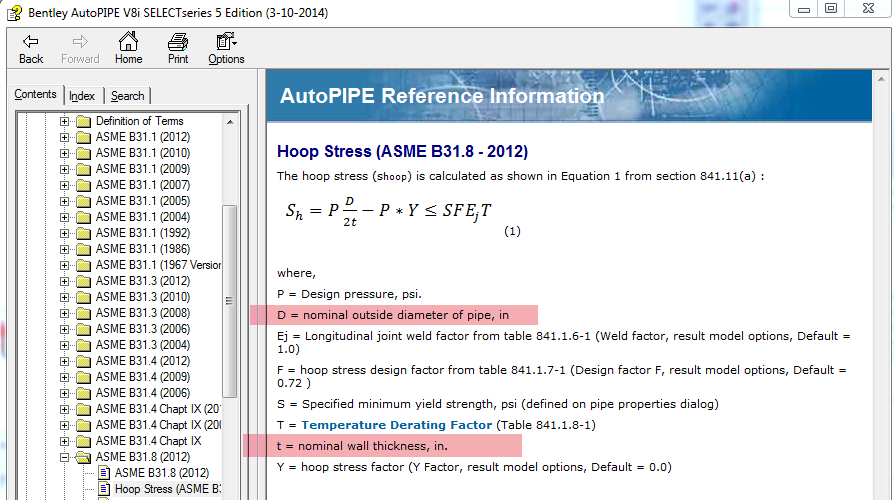

The nominal wall thickness is determined by the following formula from ASME B318 para 8411. That value of 072 is a factor for B314 Chapter IX - Offshore piping. 08 072 06 05 04. So both the codes ASME B314 and ASME B318 are pipeline design codes that cover the design fabrication installation inspection and testing of pipeline facilities. ASME B314 vs ASME B318. Pipe Wall Thickness Calculation As Per Asme B31 8 Engineering Blog.

08 072 06 05 04. For onshore pipelines and offshore platform piping the allowable pressure is the maximum allowable design pressure for the pipeline location class and facility type. ASME B318 2010 table 84116-2 design factor for pipe Class 1 location. 841114A Basic Design Factor F. A Hoop Stress page 104 Sh F1ST F1 hoop stress design factor from Table A84222-1 S specified minimum yield strength psi MPa Sh hoop stress psi MPa. Design Engineering Of Crude Oil And Natural Gas Pipelines.

What are those numbers multiplied by in other words how are thos numbers used. ASME B318-2010 Chapter VIII Offshore Gas Transmission A842 STRENGTH CONSIDERATIONS A8422 Strength Considerations During Operations A84222 Design Against Yielding. Not exceed 75 of the allowable stress in the hot condition. For location class 4 the design factor is 04 for all facility. Kindly note that the exceptions to the design factors are shown in table 84116-2 of ASME B318. Asme B31 8 Riser Calc Pdf Pipe Fluid Conveyance Plumbing.

Location class design factor for ASME B318. ASME B314 vs ASME B318. Not exceed 75 of the allowable stress in the hot condition. ASME has been defining piping safety since 1922. Some of the design factors shown in the exceptions are lesser than the actual design factor for the location class. Fianagusta Blogspot Com.

Class 1 Division 2 - A Location Class 1 where the design factor of the pipe is equal to or less than 072 but equal to or less than 080 and which has been hydrostatically tested to 11 times the maximum operating pressure. But ASME B314 deals with pipelines transporting liquids and slurries whereas ASME B318 deals with gas transmission and distribution. TABLE 841114B DESIGN FACTORS FOR STEEL PIPE CONSTRUCTION. Design Factor F Longitudinal Factor E MAWP Temperature Derating Factor T. Material Density And Specific Gravity Data Module. 04 Using Asme B31 8 2012 2016 How Is The Hoop Stress Being Calculated In Autopipe Autopipe Wiki Autopipe Bentley Communities.