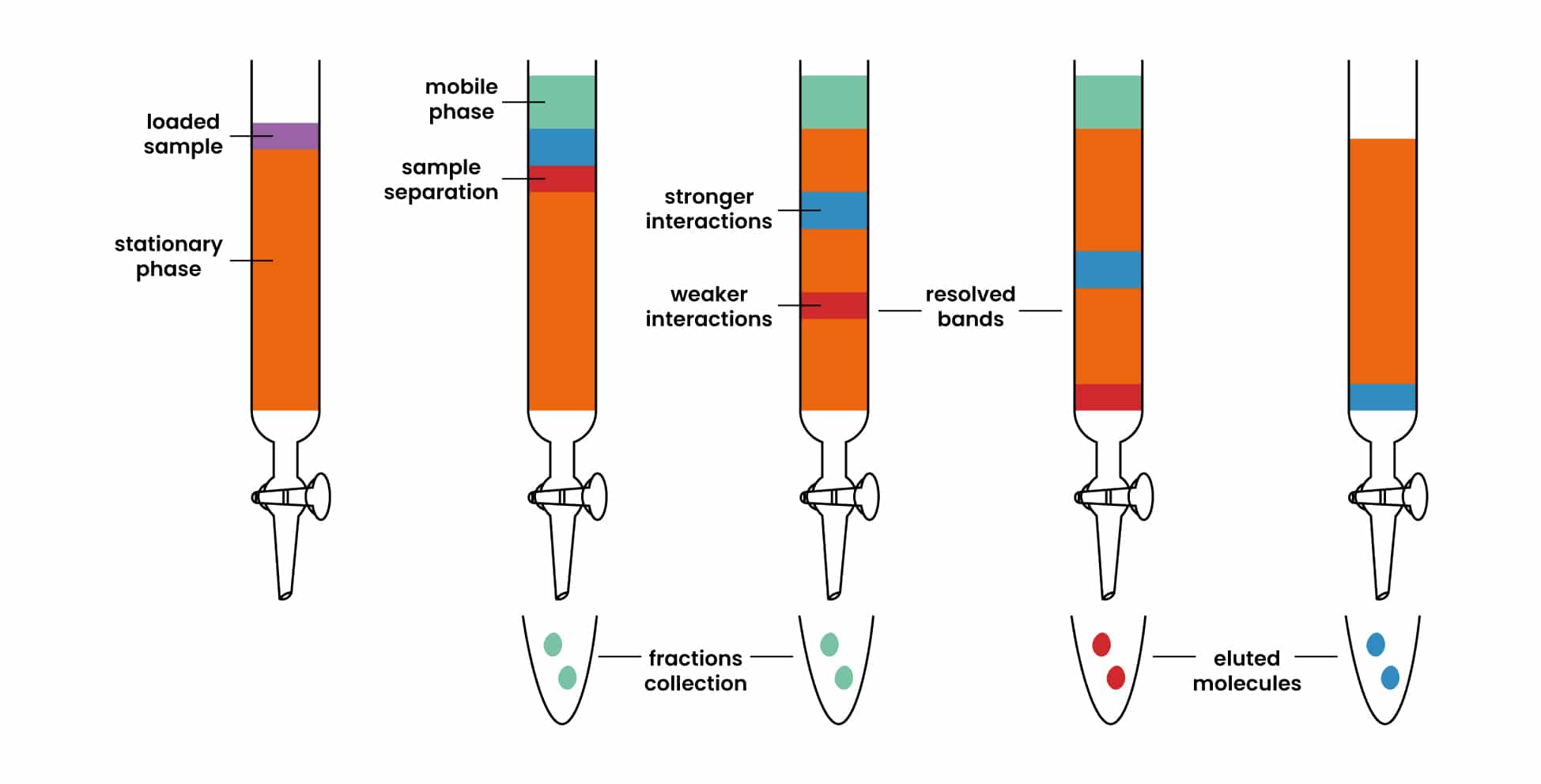

The front of the pulse is an adsorption wave and the back of the pulse is a desorption wave. Hence a multi-plate process represents a more efficient use of the resin which reduces the cost of the process. adsorption column design procedure.

Adsorption Column Design Procedure, Scale up procedure and ii. Note that an isotherm that is favorable for adsorption is unfavorable for desorption. The contacting techniques are almost identical.

Column Experiment An Overview Sciencedirect Topics From sciencedirect.com

Column Experiment An Overview Sciencedirect Topics From sciencedirect.com

The ADS can be used to design various adsorption processes such as dehydration desulfurization mercaptan removal mercury removal and other services. In that format the data comprise. Case studies show that the ADS can be successfully applied for the optimization of energy capital costs and operating conditions for an adsorption column.

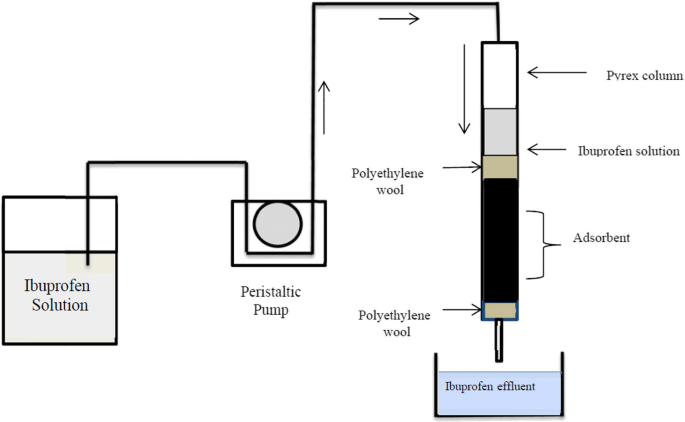

The study is limited only on the adsorption mechanism of lead Pb2 in an upflow fixed bed continuous process.

These parameters include height of bed inner column diameter particle diameter flow rate inlet concentration Reynolds number peclet number and two dimensionless parame-ters ie. Kinetic approach are available to design adsorption columns. Pu 075085085 fcAg As As fy or Pu 06375085 fcAg As As fy 7 For design purposes of tied and spirally reinforced columns respectively Pu 052 Ag 085 fc. The specifications set in the design conditions while also being as cost-effective as possible. PITTSBURGH PENNSYLVANIA 15222 Program 17020 GNR Contract 14-12-928 October 1971. In that format the data comprise.

Another Article :

Hydraulic loading within the ranges normally used has little effect on adsorption. Pu 075085085 fcAg As As fy or Pu 06375085 fcAg As As fy 7 For design purposes of tied and spirally reinforced columns respectively Pu 052 Ag 085 fc. For capacity calculation of spirally reinforced columns the following equation is to be used. A sensitivity analysis was also done to make sure the column could withstand changing conditions like temperature and contaminant concentration. In that format the data comprise. Column Chromatography Principle Procedure Applications Elution In Chromatography.

In order to design an efficient adsorption column the key design and operating parameter which affects the column performance should be recognized. The amount of biosorbent is 50. A sensitivity analysis was also done to make sure the column could withstand changing conditions like temperature and contaminant concentration. This report contains a summary of the design procedure discussion of the results and cost analysis. The study is limited only on the adsorption mechanism of lead Pb2 in an upflow fixed bed continuous process. Column Experiment An Overview Sciencedirect Topics.

In that format the data comprise. The contacting techniques are almost identical. The scaleup procedure - approach for the packed column design is as follows. In particular the most favorable isotherm is the most difficult to desorb hence the name irreversible. The amount of biosorbent is 50. Column Chromatography An Overview Sciencedirect Topics.

The column is initially free of adsorbed components. Therefore the same procedures used for the design of adsorption columns may be used for ion exchange columns. In that format the data comprise. In both approaches a breakthrough curve from the test column either laboratory or pilot scale is required and the column should be as large as possible to minimize side-wall effects. The scaleup procedure - approach for the packed column design is as follows. Adsorption Chromatography Principle Procedure Experiment Application Types Of Adsorption Chromatography And Faqs.

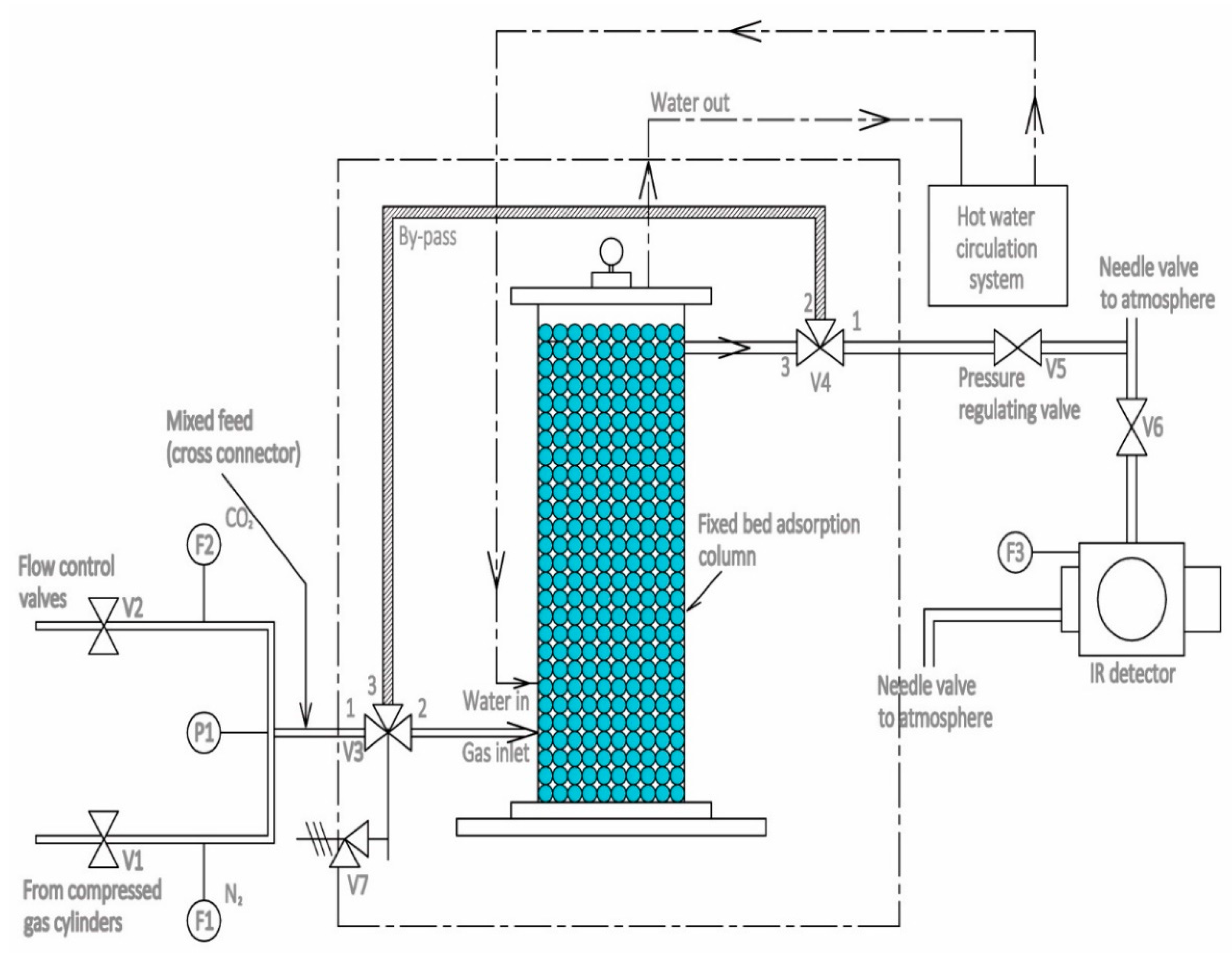

The adsorption of CrVI ions in the packed bed column is largely dependent on the bed height which is directly proportional to the quantity of EAM-CCRCBs in the column. The ADS can be used to design various adsorption processes such as dehydration desulfurization mercaptan removal mercury removal and other services. Hydraulic loading within the ranges normally used has little effect on adsorption. The procedure offers a great flexibility in terms of gas velocity thus allowing process designers to be able to customize the lengthdiameter ratio of the adsorption column. Before the adsorption bed is depleted the regenerated bed must be put into service and the roles are reversed. Materials Free Full Text Co2 Capture By Low Cost Date Pits Based Activated Carbon And Silica Gel Html.

In both approaches a breakthrough curve from the test column either laboratory or pilot scale is required and the column should be as large as possible to minimize side-wall effects. Ive designed the adsorption column. O the scale-up approach o the kinetic approach. Design Procedures The breakthrough curves for an ion exchange column and an adsorption column are similar. PROCESS DESIGN MANUAL For CARBON ADSORPTION for the ENVIRONMENTAL PROTECTION AGENCY Technology Transfer By SWINDELL-DRESSIER COMPANY A DIVISION OF PULLMAN INCORPORATED 441 SMITHFIELD ST. Scheme Of The Microextraction Procedure Using The Monolithic Spin Column Download Scientific Diagram.

This report contains a summary of the design procedure discussion of the results and cost analysis. The effect of bed height on breakthrough curve analysis was studied by. The column is initially free of adsorbed components. Hence a multi-plate process represents a more efficient use of the resin which reduces the cost of the process. For capacity calculation of spirally reinforced columns the following equation is to be used. Fixed Bed Adsorption Column Studies And Models For Removal Of Ibuprofen From Aqueous Solution By Strong Adsorbent Nano Clay Composite Springerlink.

The procedure offers a great flexibility in terms of gas velocity thus allowing process designers to be able to customize the lengthdiameter ratio of the adsorption column. Therefore if you intend to adsorb 4000 kghr of air it means you will have to put that amount and NOT 2000 kghr into each of. Before the adsorption bed is depleted the regenerated bed must be put into service and the roles are reversed. This means that the rate of adsorption is controlled by the surface reaction between the adsorbate and the unused capacity of the adsorbent. Therefore the same procedures used for the design of adsorption columns may be used for ion exchange columns. 2.

Scale up procedure and ii. The ADS can be used to design various adsorption processes such as dehydration desulfurization mercaptan removal mercury removal and other services. A sensitivity analysis was also done to make sure the column could withstand changing conditions like temperature and contaminant concentration. Packed column can be designe d using two approaches scale- up procedure and ki-netic approach. In that format the data comprise. Column Chromatography Made Simple An Easy To Follow Guide.

Case studies show that the ADS can be successfully applied for the optimization of energy capital costs and operating conditions for an adsorption column. Case studies show that the ADS can be successfully applied for the optimization of energy capital costs and operating conditions for an adsorption column. Before the adsorption bed is depleted the regenerated bed must be put into service and the roles are reversed. The specifications set in the design conditions while also being as cost-effective as possible. PROCESS DESIGN MANUAL For CARBON ADSORPTION for the ENVIRONMENTAL PROTECTION AGENCY Technology Transfer By SWINDELL-DRESSIER COMPANY A DIVISION OF PULLMAN INCORPORATED 441 SMITHFIELD ST. Schematic Design Of The First Two Column Pressure Swing Adsorption Unit Download Scientific Diagram.

The scaleup procedure - approach for the packed column design is as follows. Pu 075085085 fcAg As As fy or Pu 06375085 fcAg As As fy 7 For design purposes of tied and spirally reinforced columns respectively Pu 052 Ag 085 fc. Design Procedures The breakthrough curves for an ion exchange column and an adsorption column are similar. Case studies show that the ADS can be successfully applied for the optimization of energy capital costs and operating conditions for an adsorption column. Before the adsorption bed is depleted the regenerated bed must be put into service and the roles are reversed. Pin By Column Chromatography On Silica Gel Column Chromatography Silica Gel Gel Silica.

In that format the data comprise. A step-by-step procedure was outlined to translate the amount of adsorbents into physical dimensions of the adsorption column. This means that the rate of adsorption is controlled by the surface reaction between the adsorbate and the unused capacity of the adsorbent. The procedure for adsorption column could be found in book Unit operation Mc. The ADS can be used to design various adsorption processes such as dehydration desulfurization mercaptan removal mercury removal and other services. Change Control Management Change Control Change Management Management.

The study is limited only on the adsorption mechanism of lead Pb2 in an upflow fixed bed continuous process. This expression by Thomas for an adsorption column is given. The procedure offers a great flexibility in terms of gas velocity thus allowing process designers to be able to customize the lengthdiameter ratio of the adsorption column. The amount of carbon dioxide that is removed from the unit per day is 2352kg. The specifications set in the design conditions while also being as cost-effective as possible. How To Size An Adsorption Column.

The scaleup procedure - approach for the packed column design is as follows. The ADS can be used to design various adsorption processes such as dehydration desulfurization mercaptan removal mercury removal and other services. Adsorption process is a single-stage adsorption procedure that requires more adsorbent to achieve the same degree of adsorption as in a multi-stage multi-plate process such as packed bed chromatography. Ive designed the adsorption column. These parameters include height of bed inner column diameter particle diameter flow rate inlet concentration Reynolds number peclet number and two dimensionless parame-ters ie. How To Size An Adsorption Column.

PROCESS DESIGN MANUAL For CARBON ADSORPTION for the ENVIRONMENTAL PROTECTION AGENCY Technology Transfer By SWINDELL-DRESSIER COMPANY A DIVISION OF PULLMAN INCORPORATED 441 SMITHFIELD ST. The effect of bed height on breakthrough curve analysis was studied by. The basic process configurations of the physical plant include upflow or downflow either under force of gravity or pump pressure with fixed or moving beds. Two method including shortcut method and detail design could be used. The procedure offers a great flexibility in terms of gas velocity thus allowing process designers to be able to customize the lengthdiameter ratio of the adsorption column. Column Experiment An Overview Sciencedirect Topics.