It is generally interpreted as meaning that 85 of the particles of the size equal to the nominal micron rating will be retained by the filter. For a pot filter with the ideal proportion mixture of filter material flow rates of 1-3 Lhr can be achieved 24. activated carbon filter design calculation pdf.

Activated Carbon Filter Design Calculation Pdf, Classification of Activated Sludge Processes The activated-sludge process is often classified on the basis of loading rate may be expressed as a volumetric loading rate SRT or FM Classified as High rate Conventional Low rate Conventional Activated Sludge Conventional systems provide BOD5 removal efficiencies of 85 to 95. Size of Activated Carbon Particles Used in Fixed-Bed Adsorption Typically carbon particle sizes between 04 and 25 mm are used in fixed bed adsorption applications This size range results from a practical compromise between limiting the pressure drops on one hand and providing adequate surface area and promote mass transfer for. It is generally interpreted as meaning that 85 of the particles of the size equal to the nominal micron rating will be retained by the filter.

Empty Bed Contact Time The Key For Micropollutant Removal In Activated Carbon Filters Sciencedirect From sciencedirect.com

Empty Bed Contact Time The Key For Micropollutant Removal In Activated Carbon Filters Sciencedirect From sciencedirect.com

When properly designed operated and maintained carbon adsorbers can achieve high VOC removal efficiencies of 95 to 99 percent at input VOC concentrations of between 500 and 2000 ppm in air. WQA Glossary of Terms Third Edition 3-97. It is generally interpreted as meaning that 85 of the particles of the size equal to the nominal micron rating will be retained by the filter.

Sand Filter An Overview Sciencedirect Topics.

Bmp T8 10 Basic Sand Filter Basin. Empty Bed Contact Time is calculated as volume of empty bed divide by flow rate. For Chlorine contact time is 2 min. For a pot filter with the ideal proportion mixture of filter material flow rates of 1-3 Lhr can be achieved 24. When properly designed operated and maintained carbon adsorbers can achieve high VOC removal efficiencies of 95 to 99 percent at input VOC concentrations of between 500 and 2000 ppm in air. A one cubic ft GAC filter is 75 gallons of GAC.

Another Article :

Activated Carbon Water Filtration. Contact time is defined in minutes and below is the some examples. 1 The activated carbon filter AMK series adsorbs oil vapor contained in the compressed air and removes the odors derived from it but does not remove all odors. Classification of Activated Sludge Processes The activated-sludge process is often classified on the basis of loading rate may be expressed as a volumetric loading rate SRT or FM Classified as High rate Conventional Low rate Conventional Activated Sludge Conventional systems provide BOD5 removal efficiencies of 85 to 95. Filter Area m2 DAF. Advanced Biological Activated Carbon Filter For Removing Pharmaceutically Active Compounds From Treated Wastewater Sciencedirect.

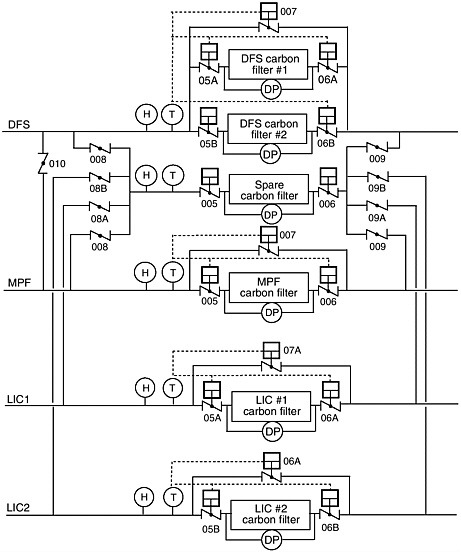

For H 2 S contact time is 4 min. ACTIVATED CARBON ADSORPTION FS-TER-002 Page 6 of 18 3- DESIGN AND OPERATION 31- Description Continuous flow GAC systems are usually composed of carbon filters virgin and spent carbon storage carbon transport systems and carbon regeneration systems. The addition of an activated carbon filter system the PFS to the baseline incineration process will impose several new design requirements. Filter types and selection An array of options Gravity vs. Activated Carbon Water Filtration. Global United States European Union And China Activated Carbon Filters Market Research Report 2019 2025 Activated Carbon Filter Carbon Filter Activated Carbon.

Pressure Sand Filter Design Pdf. Empty Bed Contact Time is calculated as volume of empty bed divide by flow rate. For Chlorine contact time is 2 min. Operating Flow Rate m3hr υAF Bed Volume m3 t Contact time min. Activated Carbon Filter Calculation. Design And Selection Of Activated Carbon Air And Gas Treatment Systems Jacobi Services.

A flow of water through that filter at 25 gpm has an EBCT of 7525 3 minutes. Bmp T8 10 Basic Sand Filter Basin. Removal efficiencies greater than 98 percent can be achieved for dilute waste streams. Candle ceramic filters are sometimes filled with activated carbon to increase water purity. A flow of water through that filter at 25 gpm has an EBCT of 7525 3 minutes. Household Water Treatment Mechanical Filtration Methods And Devices Uga Cooperative Extension.

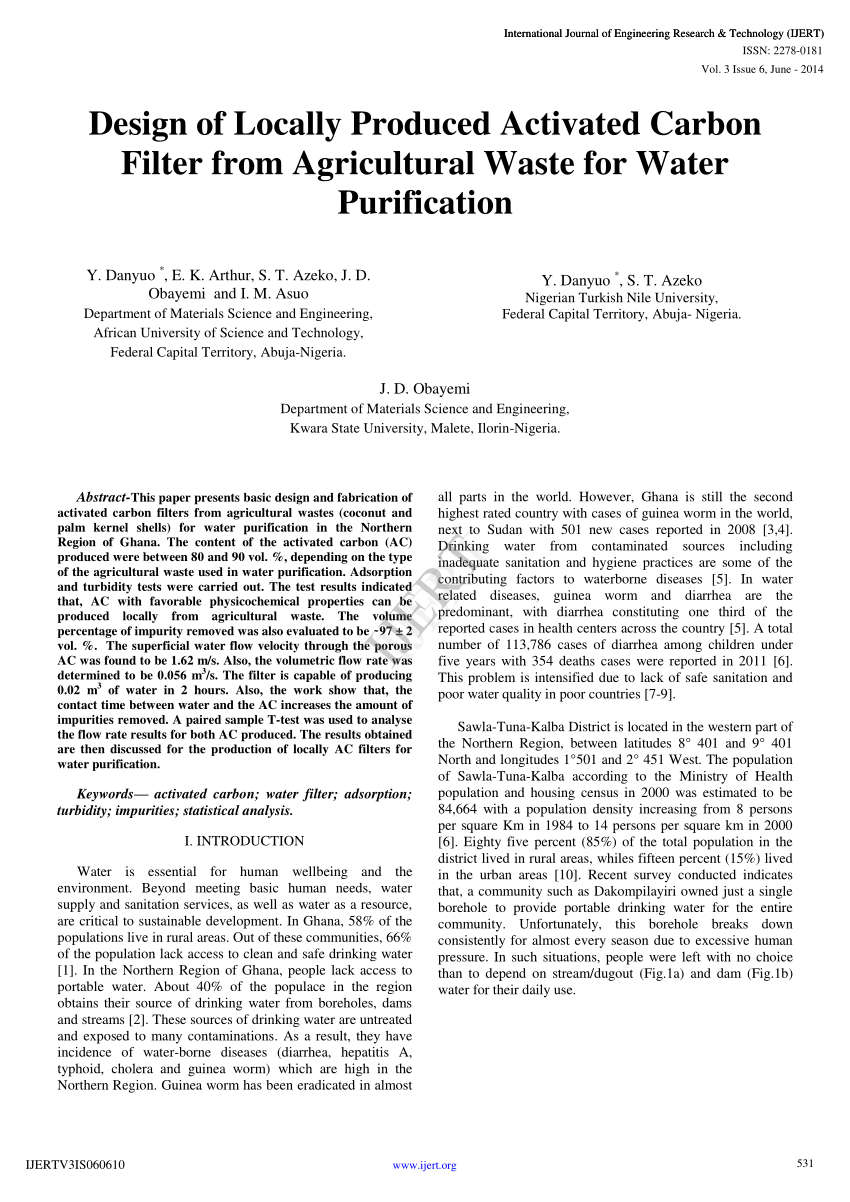

When properly designed operated and maintained carbon adsorbers can achieve high VOC removal efficiencies of 95 to 99 percent at input VOC concentrations of between 500 and 2000 ppm in air. Activated Carbon Water Filtration. Http Www Solutionsforwater Org Wp Content Uploads 2011 12 Slow Sand Filtration Introduction 7 Mb 16 Dec 2011 Pdf. If this is not acceptable please consult SMC. For VOC contact time is 7 min. Pdf Design Of Locally Produced Activated Carbon Filter From Agricultural Waste For Water Purification.

PArT III dEsIgn And ProcurEMEnT oF AcTIvATEd cArbon sysTEMs 135 8 gravity gAc Treatment system design 137 Design and Construction. Filter Velocity m3m2hr AAF. Activated Carbon Filter Calculation. An activated carbon unit shall be designed such that the minimum empty bed residence time is at least 3 seconds at the maximum design air flow. When properly designed operated and maintained carbon adsorbers can achieve high VOC removal efficiencies of 95 to 99 percent at input VOC concentrations of between 500 and 2000 ppm in air. Pin On Aquarium Filter.

Empty Bed Contact Time is calculated as volume of empty bed divide by flow rate. Activated Carbon Filter Calculation. Facility Design with a Carbon Filter System. Candle ceramic filters are sometimes filled with activated carbon to increase water purity. Activated Carbon Basics TOC Removal Testing Methods Activated Carbon Performance Activated Carbon Delivery Systems Cost Data 0 20 40 60 80 100 120 140 160 0 10 20 30 40 50 60 70 THMFP ug L Full-scaleservicetimedays THMFP Logistic6Function6Fit MCL 806MCL Filtersorb 300 100 x 200 mesh fraction EBCT 12615 minutes. Empty Bed Contact Time The Key For Micropollutant Removal In Activated Carbon Filters Sciencedirect.

The suspended particles removed during filtration range from 0001 to 50 microns and larger. For VOC contact time is 7 min. Http Www Solutionsforwater Org Wp Content Uploads 2011 12 Slow Sand Filtration Introduction 7 Mb 16 Dec 2011 Pdf. The addition of an activated carbon filter system the PFS to the baseline incineration process will impose several new design requirements. Activated Carbon AC is a. Pdf Performance Of Activated Carbon In Water Filters.

Page 3-20 Pressurized Downflow Contactor Rocky River Ohio 3-38 3-21 Typical Downflow Gravity Contactor 3-39 3-22 Carbon Transfer with Upflow Column in Service 3-41 3-23 Carbon Delivery Rate 2-inch pipe 3-43 3-24 Carbon Delivery Rate 1-inch pipe 3-44 3-25 Pressure Drop of Carbon-Water Slurries 2-inch pipe 3-45 3-26 Blowcase Transport System 3-46 3. CARTRIDGE FILTER - ACTIVATED CARBON Granular Activated Carbon Filter Cartridge Composed of lignite-based granular activated carbon in an upflow cartridge design for removing chlorine feed water Cartridge is designed to allow water to enter the bottom of the cartridge then filtered through the entire carbon bed before exiting at the top. Download scientific diagram Design concept for the activated carbon water filter. The carbon filter typically consists of a linear steel column orn. Filter rating indicating the approximate size particle the majority of which will not pass through the filter. Design And Operation Of High Rate Filters Kawamura 1999 Journal Awwa Wiley Online Library.

—– LIST OF FIGURES - Continued Figure No. Activated Carbon Basics TOC Removal Testing Methods Activated Carbon Performance Activated Carbon Delivery Systems Cost Data 0 20 40 60 80 100 120 140 160 0 10 20 30 40 50 60 70 THMFP ug L Full-scaleservicetimedays THMFP Logistic6Function6Fit MCL 806MCL Filtersorb 300 100 x 200 mesh fraction EBCT 12615 minutes. A flow of water through that filter at 25 gpm has an EBCT of 7525 3 minutes. Filter rating indicating the approximate size particle the majority of which will not pass through the filter. It is generally interpreted as meaning that 85 of the particles of the size equal to the nominal micron rating will be retained by the filter. Biofiltration Best Practices For Design And Operation Hazen And Sawyer.

ACTIVATED CARBON ADSORPTION FS-TER-002 Page 6 of 18 3- DESIGN AND OPERATION 31- Description Continuous flow GAC systems are usually composed of carbon filters virgin and spent carbon storage carbon transport systems and carbon regeneration systems. The suspended particles removed during filtration range from 0001 to 50 microns and larger. Facility Design with a Carbon Filter System. Size of Activated Carbon Particles Used in Fixed-Bed Adsorption Typically carbon particle sizes between 04 and 25 mm are used in fixed bed adsorption applications This size range results from a practical compromise between limiting the pressure drops on one hand and providing adequate surface area and promote mass transfer for. An activated carbon unit shall be designed such that the minimum empty bed residence time is at least 3 seconds at the maximum design air flow. Sand Filter An Overview Sciencedirect Topics.

Facility Design with a Carbon Filter System. Sand Filter An Overview Sciencedirect Topics. Activated Carbon AC is a. Flow rate of ceramic water filters are controlled by surface area and the amount of additives. Activated carbon filtration is a commonly used technology based on the adsorption of contaminants onto the surface of a filter. Advanced Biological Activated Carbon Filter For Removing Pharmaceutically Active Compounds From Treated Wastewater Sciencedirect.

If this is not acceptable please consult SMC. Activated Carbon AC is a. Operating Flow Rate m3hr υAF Bed Volume m3 t Contact time min. —– LIST OF FIGURES - Continued Figure No. The carbon filter typically consists of a linear steel column orn. 4 Facility Design With A Carbon Filter System Carbon Filtration For Reducing Emissions From Chemical Agent Incineration The National Academies Press.

Empty Bed Contact Time is calculated as volume of empty bed divide by flow rate. Removal efficiencies greater than 98 percent can be achieved for dilute waste streams. This method is effective in removing certain organics such as unwanted taste and odours micropollutants chlorine fluorine or. Activated carbon filtration is a commonly used technology based on the adsorption of contaminants onto the surface of a filter. Contact time is defined in minutes and below is the some examples. Pdf Design Of Locally Produced Activated Carbon Filter From Agricultural Waste For Water Purification.

Filter Diameter m L AF. When properly designed operated and maintained carbon adsorbers can achieve high VOC removal efficiencies of 95 to 99 percent at input VOC concentrations of between 500 and 2000 ppm in air. 61 4-12 Adsorber operation schematics. Filter Diameter m L AF. For H 2 S contact time is 4 min. Woven Textiles Principles Technologies And Applications Ebook Weaving Textiles Textiles Principles.