Not a simple process. Describes novel design principles that allow horn diameters and their amplitude gain factors to be independent variables. acoustic horn design principles.

Acoustic Horn Design Principles, This room modal behavior is the worst one possible having two first modes coinciding with each other and their third mode coinciding with the second vertical mode at about 120Hz. Reactive silencer design is based either on the principle of a Helmholtz resonator or an expansion chamber and requires the use of acoustic transmission line theory. Hornm outputs outputs plots of the horn shape and impedance at the mouth.

Pdf Matching A Transducer To Water At Cavitation Acoustic Horn Design Principles From researchgate.net

Pdf Matching A Transducer To Water At Cavitation Acoustic Horn Design Principles From researchgate.net

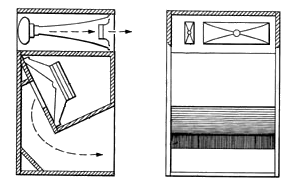

In this work two acoustic horns were installed symmetrically on the outer ends of the main magnet of the split MRI system after the asymmetric gradient assembly design. The corner horn design should be made either for a concrete well-evaluated room acoustically in advance or both room-horn combinations should be designed together. The red solid line is the wide sheet for the top and bottom and the solid line is the narrower sheet for the sides.

Correct material must be selected horns must be balanced designed for the required amplitude and.

Horns made of alloy steel can be heat-treated for a wear-resistant surface but the low acoustical efficiency of steel limits its use to. Horn design is. In this work two acoustic horns were installed symmetrically on the outer ends of the main magnet of the split MRI system after the asymmetric gradient assembly design. This is the sound we hear. ACOUSTIC CAVITATION THEORY AND EQUIPMENT DESIGN PRINCIPLES FOR INDUSTRIAL APPLICATIONS OF HIGH-INTENSITY ULTRASOUND Physics Research and Technology Paperback Alexey Peshkovsky Sergei Peshkovsky Paperback. In a horn the acoustical impedance will increase when the cross-section of the horn decreases as a decrease in cross sec-tion will limit the flow of air at a certain pressure.

Another Article :

In a horn the acoustical impedance will increase when the cross-section of the horn decreases as a decrease in cross sec-tion will limit the flow of air at a certain pressure. Acoustic horn design principles. Normally this driver would have an efficiency around 87 db so we have gained around 19 db. Firstly the theoretical dimensions of the horns are calculated. The acoustic horn plays a very vital part in high energy ultrasonic machining and its design is critical to the quality and the efficiency of machining. Avantgarde Acoustic Duo Mezzo Xd Horn Best Of High End.

When a diaphragm vibrates pressure waves are created in front of it. Only from the stage. The small end of the horn where the driver is attached. HELLA enforces the principles of developing state-of-the-art products and ensures the delivery of world-class horns to our customers. This room modal behavior is the worst one possible having two first modes coinciding with each other and their third mode coinciding with the second vertical mode at about 120Hz. Horn Technology Avantgarde Acoustic Hornloudspeaker.

Ultrasonic welding uses an acoustic tool called an ultrasonic horn made to match your parts design. Since sound is a pressure disturbance we need a pressure gauge of some sort Since sound exerts a pressure we can use it to drive an electrical generator Since sound is a wave we can measure simultaneously at two or more. Hornm outputs outputs plots of the horn shape and impedance at the mouth. A common form consists of a compression driver which produces sound waves with a small metal diaphragm vibrated by an electromagnet attached to a horn a flaring duct to conduct the sound waves to the open air. A multitude of useful physical and. Horn Technology Avantgarde Acoustic Hornloudspeaker.

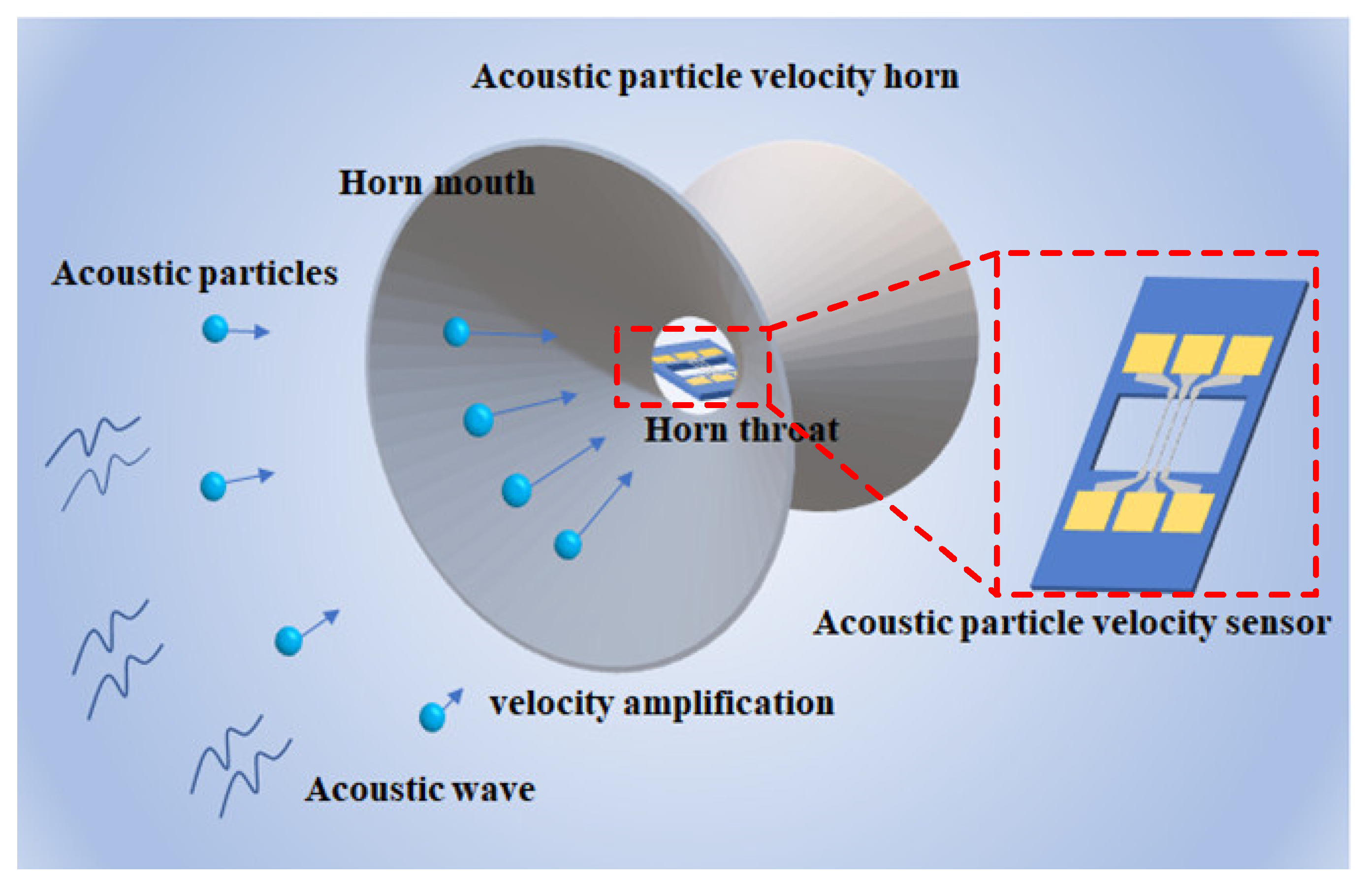

Describes novel design principles that allow horn diameters and their amplitude gain factors to be independent variables. Not a simple process. Microphone Principles Concepts. Firstly the theoretical dimensions of the horns are calculated. The flat sheet fabrication plot is for manufacturing a square horn from sheet metal or plywood. Sensors Free Full Text Design And Optimization Of Sensitivity Enhancement Package For Mems Based Thermal Acoustic Particle Velocity Sensor Html.

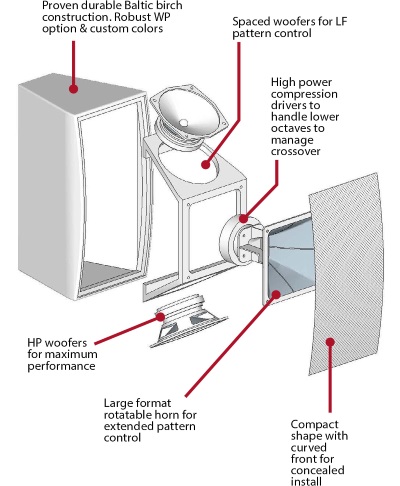

Hornm outputs position and radius design vectors. In a horn the acoustical impedance will increase when the cross-section of the horn decreases as a decrease in cross sec-tion will limit the flow of air at a certain pressure. Now you weill notice that fields are filled in. HELLA enforces the principles of developing state-of-the-art products and ensures the delivery of world-class horns to our customers. The sound generated by a loudspeaker or any unsteady movement of a solid boundary are examples of the sound generation mechanism in classical acoustics. Eastern Acoustic Works Unveils Mkd Installation Loudspeakers Prosoundweb.

At a specific frequency the cavity will resonate and the waves in the exhaust pipe are reflected back. Hornm outputs outputs plots of the horn shape and impedance at the mouth. An exaggeration of short acoustic path-lengths is a bathroom. Five-element matching horns31. Describes novel design principles that allow horn diameters and their amplitude gain factors to be independent variables. Pdf Matching A Transducer To Water At Cavitation Acoustic Horn Design Principles.

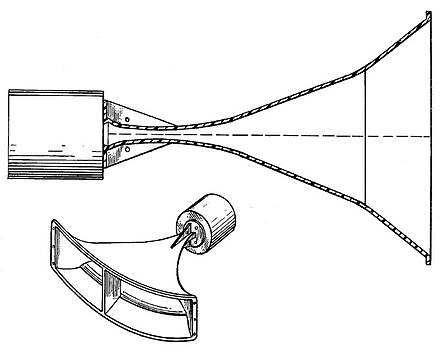

Horns made of alloy steel can be heat-treated for a wear-resistant surface but the low acoustical efficiency of steel limits its use to. Hornm outputs position and radius design vectors. Design principlesThe theory of acoustic horns is based on the problem of longitudinal vibrations of multi-element rods that have cylindrical elements and elements of variable cross-sections. A horn loudspeaker is a loudspeaker or loudspeaker element which uses an acoustic horn to increase the overall efficiency of the driving element. Acoustic Horn Design Principles Shows why conventional ultrasonic horns cannot be scaled up without sacrificing high ultrasonic amplitudes. Horn Loudspeaker Wikiwand.

Long acoustic path-lengths are echoes churches and cause difficulty for musicians to play in time. In a Helmholtz resonator design a cavity is attached to the exhaust pipe. Acoustic horn design principles Ultrasonics Sonochemistry vol. Design principlesThe theory of acoustic horns is based on the problem of longitudinal vibrations of multi-element rods that have cylindrical elements and elements of variable cross-sections. A horn loudspeaker is a loudspeaker or loudspeaker element which uses an acoustic horn to increase the overall efficiency of the driving element. Pdf Finite Element Analysis Assisted Design Of Ultrasonic Horn For Plastic Welding.

A common form consists of a compression driver which produces sound waves with a small metal diaphragm vibrated by an electromagnet attached to a horn a flaring duct to conduct the sound waves to the open air. In classical acoustics the generation of sound is considered to be a boundary condition problem. Acoustics is a first order approximation in which non-linear effects are neglected. Understanding the following principles and your application requirements will shed much light on this technology. The horn may be viewed as an acoustic impedance transformer. Pdf Matching A Transducer To Water At Cavitation Acoustic Horn Design Principles.

Only from the stage. An exaggeration of short acoustic path-lengths is a bathroom. In classical acoustics the generation of sound is considered to be a boundary condition problem. Now you weill notice that fields are filled in. Auto generate horn Select ToolsSystem designwith driver In this case lets choose 40 - 150 Hz. Loudspeaker An Overview Sciencedirect Topics.

In a horn the acoustical impedance will increase when the cross-section of the horn decreases as a decrease in cross sec-tion will limit the flow of air at a certain pressure. Hornm outputs position and radius design vectors. Press calculate and view the results. Microphone Principles Concepts. A multitude of useful physical and. Horn Design Show 2017.

Horns made of alloy steel can be heat-treated for a wear-resistant surface but the low acoustical efficiency of steel limits its use to. In a horn the acoustical impedance will increase when the cross-section of the horn decreases as a decrease in cross sec-tion will limit the flow of air at a certain pressure. Not a simple process. The red solid line is the wide sheet for the top and bottom and the solid line is the narrower sheet for the sides. The sound generated by a loudspeaker or any unsteady movement of a solid boundary are examples of the sound generation mechanism in classical acoustics. Horn Design Show 2016.

Since sound is a pressure disturbance we need a pressure gauge of some sort Since sound exerts a pressure we can use it to drive an electrical generator Since sound is a wave we can measure simultaneously at two or more. The using of multiple function acoustic horn can reduce machining time very effectively. Ultrasonic welding uses an acoustic tool called an ultrasonic horn made to match your parts design. Correct material must be selected horns must be balanced designed for the required amplitude and. In classical acoustics the generation of sound is considered to be a boundary condition problem. Horn Loudspeaker Wikiwand.

ACOUSTIC CAVITATION THEORY AND EQUIPMENT DESIGN PRINCIPLES FOR INDUSTRIAL APPLICATIONS OF HIGH-INTENSITY ULTRASOUND Physics Research and Technology Paperback Alexey Peshkovsky Sergei Peshkovsky Paperback. Press calculate and view the results. Nova Science Pub Inc October 31 2010 ISBN-10. ACOUSTIC SIGNAL UNITS HELLAs horns trumpet horns. The using of multiple function acoustic horn can reduce machining time very effectively. Horn Loudspeaker Wikiwand.

Not a simple process. Auto generate horn Select ToolsSystem designwith driver In this case lets choose 40 - 150 Hz. Ultrasonic welding uses an acoustic tool called an ultrasonic horn made to match your parts design. Correct material must be selected horns must be balanced designed for the required amplitude and. Their design is both striking and resistant to inclement weather. Fully Integrated Fused Quartz Acoustic Horns For Structural Health Monitoring The Journal Of The Acoustical Society Of America Vol 146 No 3.